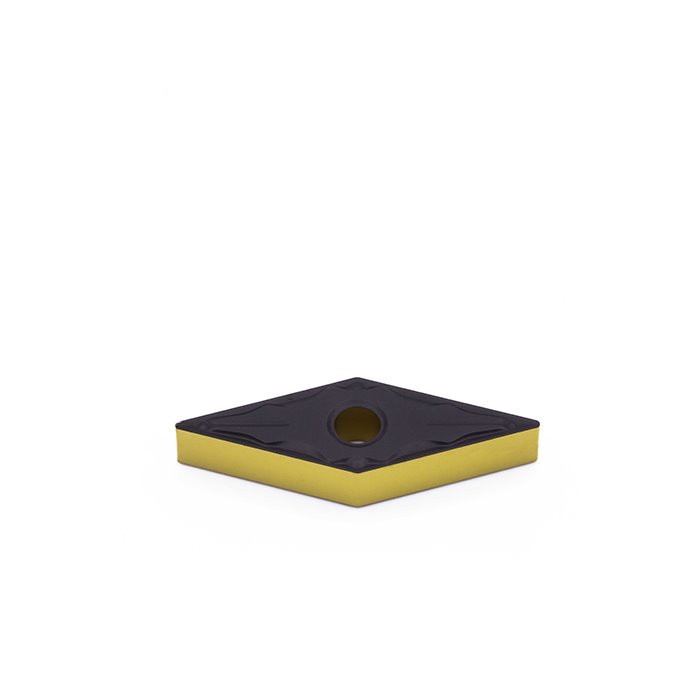

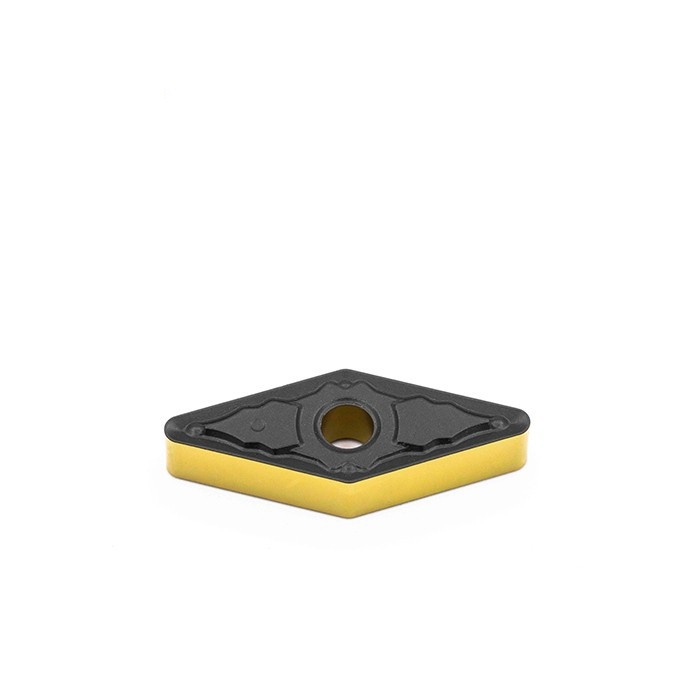

CVD Coated Insert for Extended Tool Life and Improved Productivity Details

Product Information:

This kind of VNMG Insert is made of high quality alloy metal with advanced technology. The surface is treated with CVD coating to extend the cutting life. The unique V shape design with negative angles guarantees efficient machining and high stability. The combination of different chip breakers and grades will help it to deal with different working condition and multiple operations.

In addition, it has the advantages of high hardness, high efficiency, high accuracy, corrosion resistance, long service life, smooth appearance.

We can also provide customized service to meet the requirements of different customers.

Specifications:

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 |

P Semi Finishing | VNMG110404-AM | 0.80-2.50 | 0.15-0.36 | • | O | • |

| O | O |

|

|

|

|

|

|

VNMG110408-AM | 1.00-2.50 | 0.17-0.36 | • | O | • |

| O | O |

|

|

|

|

|

|

VNMG160404-AM | 0.80-3.00 | 0.15-0.36 | • | O | • |

| O | O |

|

|

|

|

|

|

VNMG160408-AM | 1.00-2.50 | 0.17-0.36 | • | O | • |

| O | O |

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

|

|

|

|

|

|

|

|

|

|

|

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1525 | VY1330 |

M Finishing | VNMG160404-BF | 0.25-3.30 | 0.05-0.15 |

|

|

|

|

| • | • |

| O |

| O |

|

VNMG160408-BF | 0.55-3.30 | 0.10-0.30 |

|

|

|

|

| • | • |

| O |

| O |

|

VNMG160412-BF | 0.75-3.30 | 0.15-0.45 |

|

|

|

|

| • | • |

| O |

| O |

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

CVD

|

VT3020 | VT3040 | VT3315 | VT3415 |

K Semi Finishing | VNMG160404-CM | 0.40-3.30 | 0.08-0.25 |

|

| • | O |

VNMG160408-CM | 0.80-3.30 | 0.15-0.45 |

|

| • | O |

VNMG160412-CM | 1.20-3.30 | 0.25-0.65 |

|

| • | O |

• : Recommended Grade

O: Optional Grade

Application:

The VNMG Insert is mainly used in the fields of small part turning, general turning, metal turning, milling, cutting and grooving, thread turning, etc.

FAQ:

What is the difference between positive and negative inserts?

The difference between Positive and Negative insert lies in they with different clearance angle. The clearance angle of negative insert is o degree . the positive inserts have clearance angle between 1 degree to 90 degree.

Which insert type is the best choice for rough machining?

When you need roughing and general turning .the negative inserts are the first and best option. this type of insert allows deeper depths of cut and higher feed rates due to strong insert shapes and thickness.

Our Company

Package Shipment