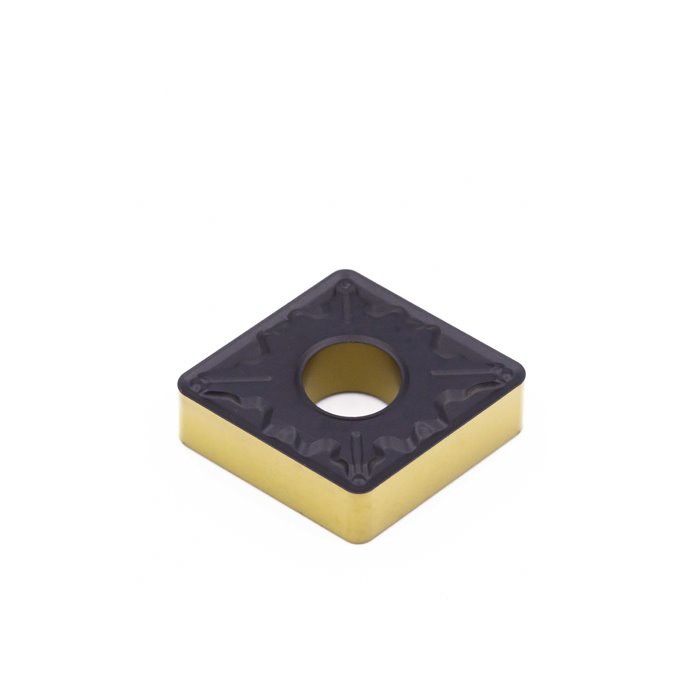

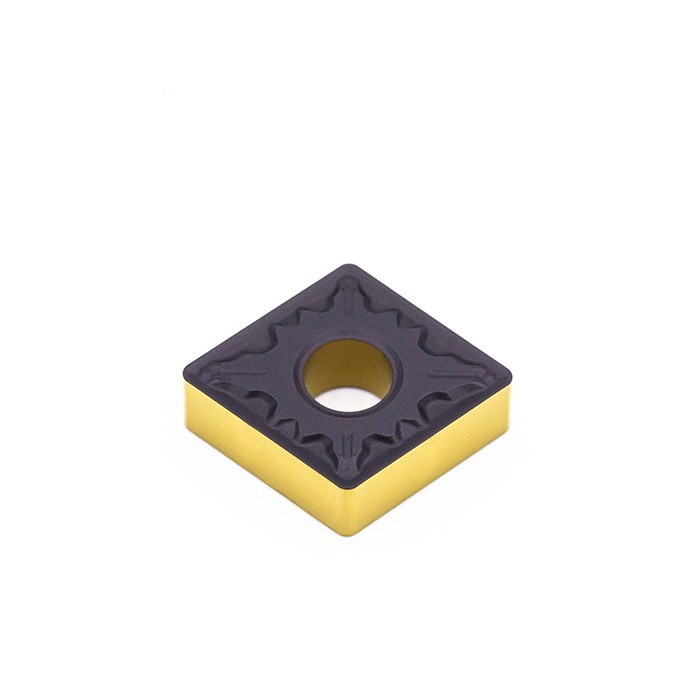

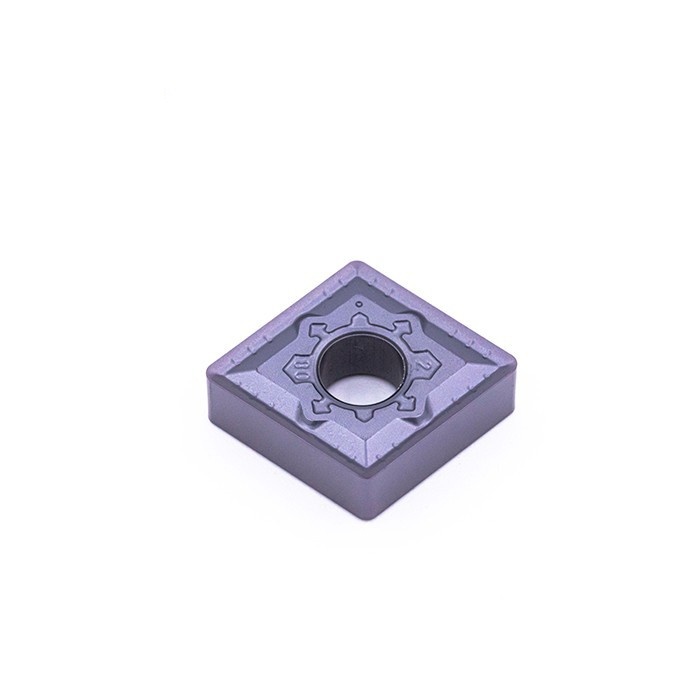

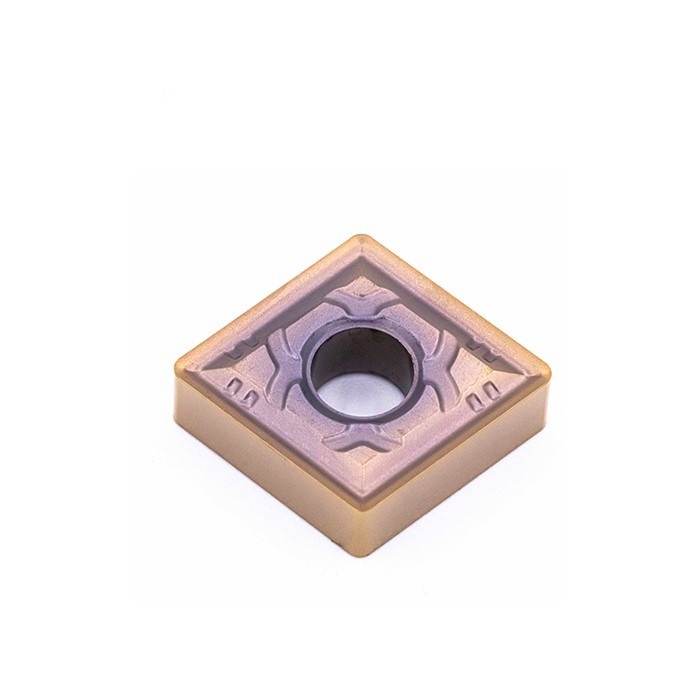

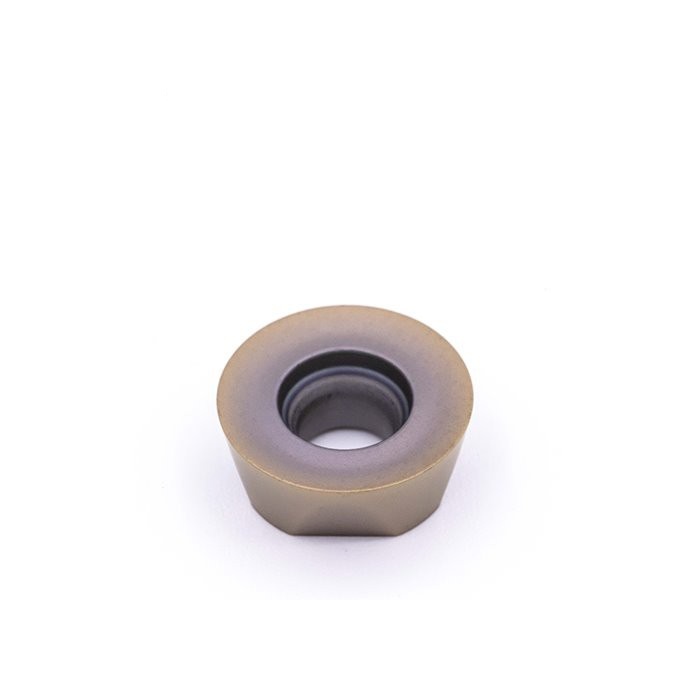

CNMG Turning Insert for Reliable Performance in Turning and Boring Details

Product Information:

CNMG Double-Sided 80° Rhombic turning Inserts.it can deal with multiple operations by combining different chip breakers and grades.CNMG 80° Turning Inserts feature an advanced coating over a very deformation-resistant unalloyed carbide substrate. which will bring efficient machining and high stability.Universal high productivity grade for turning.Good balance of productivity and reliability.it’s an good ideal choice for roughing.finishing and general machining.

Specifications:

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215

| VT4225 | VT4225 | VT4325 | VT4235 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 |

P Semi Finishing | CNMG120404-AM | 0.60-6.40 | 0.10-0.30 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG120408-AM | 1.20-6.40 | 0.20-0.60 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG120412-AM | 1.80-6.40 | 0.30-0.90 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG120416-AM | 2.40-6.40 | 0.12-0.40 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG160608-AM | 1.20-8.10 | 0.10-0.30 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG160612-AM | 1.80-8.10 | 0.20-0.60 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG160616-AM | 2.40-8.10 | 0.30-0.90 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG190608-AM | 1.20-9.70 | 0.20-0.60 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG190612-AM | 1.80-9.70 | 0.30-0.90 | • | O | • |

| O | O |

|

|

|

|

|

|

CNMG190616-AM | 2.40-9.70 | 0.40-1.20 | • | O | • |

| O | O |

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

CVD

| PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 |

P Rough Machining | CNMG120408-AR | 1.45-5.20 | 0.15-0.32 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG120412-AR | 2.15-5.20 | 0.25-0.50 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG120416-AR | 2.90-5.20 | 0.30-0.65 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG160608-AR | 1.45-6.40 | 0.15-6.35 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG160612-AR | 2.15-6.40 | 0.24-0.50 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG160616-AR | 2.90-6.40 | 0.30-0.65 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG190608-AR | 1.45-7.70 | 0.15-0.35 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG190612-AR | 2.15-7.70 | 0.25-0.50 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG190616-AR | 2.90-7.70 | 0.30-0.65 |

|

| • | O |

|

|

|

|

|

|

|

|

CNMG190624-AR | 4.30-7.70 | 0.45-0.95 |

|

| • | O |

|

|

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1525 | VY1330 |

M Finishing | CNMG090304-BF | 0.25-2.40 | 0.05-0.15 |

|

|

|

|

| • | • |

| O |

| O | O |

CNMG090308-BF | 0.50-2.40 | 0.10-0.30 |

|

|

|

|

| • | • |

| O |

| O | O |

CNMG120404-BF | 0.25-3.20 | 0.05-0.15 |

|

|

|

|

| • | • |

| O |

| O | O |

CNMG120408-BF | 0.50-3.20 | 0.10-0.30 |

|

|

|

|

| • | • |

| O |

| O | O |

CNMG120412-BF | 0.75-3.20 | 0.15-0.45 |

|

|

|

|

| • | • |

| O |

| O | O |

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1525 | VY1330 |

M Semi Finishing | CNMG120404-BM | 0.30-4.30 | 0.08-0.25 |

|

|

|

|

| O | O | • | O |

| O |

|

CNMG120408-BM | 0.65-4.30 | 0.15-0.45 |

|

|

|

|

| O | O | • | O |

| O |

|

CNMG120412-BM | 0.95-4.30 | 0.20-0.65 |

|

|

|

|

| O | O | • | O |

| O |

|

CNMG160608-BM | 0.65-5.30 | 0.15-0.45 |

|

|

|

|

| O | O | • | O |

| O |

|

CNMG160612-BM | 0.95-5.30 | 0.25-0.65 |

|

|

|

|

| O | O | • | O |

| O |

|

CNMG160616-BM | 1.30-5.30 | 0.30-0.90 |

|

|

|

|

| O | O | • | O |

| O |

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD |

VT3020 | VT3040 | VT3315 | VT3415 |

K Semi Finishing | CNMG120404-CM | 0.40-4.30 | 0.08-0.25 |

|

| • |

|

CNMG120408-CM | 0.80-4.30 | 0.15-0.45 |

|

| • |

|

CNMG120412-CM | 1.20-4.30 | 0.20-0.65 |

|

| • |

|

CNMG160612-CM | 1.20-5.30 | 0.25-0.65 |

|

| • |

|

CNMG160616-CM | 1.60-5.30 | 0.30-0.90 |

|

| • |

|

CNMG190612-CM | 1.20-6.40 | 0.25-0.65 |

|

| • |

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1528 | VY1330 |

M Rough Machining | CNMG120404-BR | 0.30-4.30 | 0.08-0.25 |

|

|

|

| O | O | O | • |

|

| • | O |

CNMG120408-BR | 0.65-4.30 | 0.15-0.45 |

|

|

|

| O | O | O | • |

|

| • | O |

CNMG120412-BR | 0.95-4.30 | 0.25-0.65 |

|

|

|

| O | O | O | • |

|

| • | O |

CNMG160608-BR | 0.65-5.30 | 0.15-0.45 |

|

|

|

| O | O | O | • |

|

| • | O |

CNMG160612-BR | 0.95-5.30 | 0.25-0.65 |

|

|

|

| O | O | O | • |

|

| • | O |

CNMG160616-BR | 1.25-5.30 | 0.30-0.90 |

|

|

|

| O | O | O | • |

|

| • | O |

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1030 |

S Semi Finishing | CNMG120404-DM | 0.40-4.30 | 0.08-0.25 |

|

|

|

| O |

|

| O | O | • | O | • | O |

CNMG120408-DM | 0.80-4.30 | 0.15-0.45 |

|

|

|

| O |

|

| O | O | • | O | • | O |

CNMG120412-DM | 1.20-4.30 | 0.25-0.65 |

|

|

|

| O |

|

| O | O | • | O | • | O |

CNMG120416-DM | 1.60-4.30 | 0.30-0.90 |

|

|

|

| O |

|

| O | O | • | O | • | O |

• : Recommended Grade

O: Optional Grade

Application:

Dedicated grades and geometries for all applications and materials.CNMG 80° Turning Inserts is an ideal choice for rough, semi-finishing and finishing machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys under stable conditions. It also performs well machining hardened and short chipping materials.

FAQ:

What are your main products?

Estool cutting tools company’s main product are turning insert.milling insert.drilling insert.threading inserts.grooving inserts and aluminium machining inserts.

What are inserts made of?

Almost all the inserts consist of cemented carbide, which results from a combination of tungsten carbide (WC) and cobalt (Co). The hard particles within the insert are WC, while Co can be thought of as the glue that holds the insert together.

What is CNMG insert?

This CNMG Insert is suitable for high speed continuous cutting. Very durable and with superior finish.good choice for CNC turning inserts.

Our Company

Package Shipment