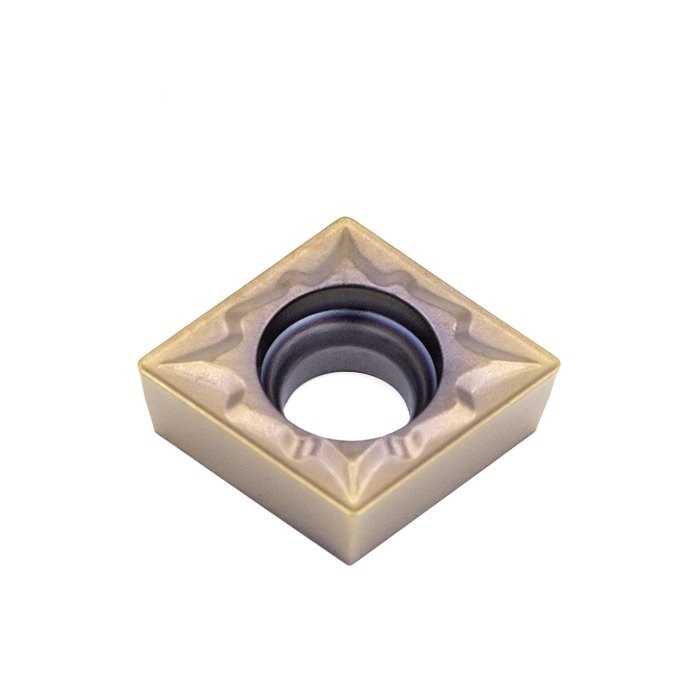

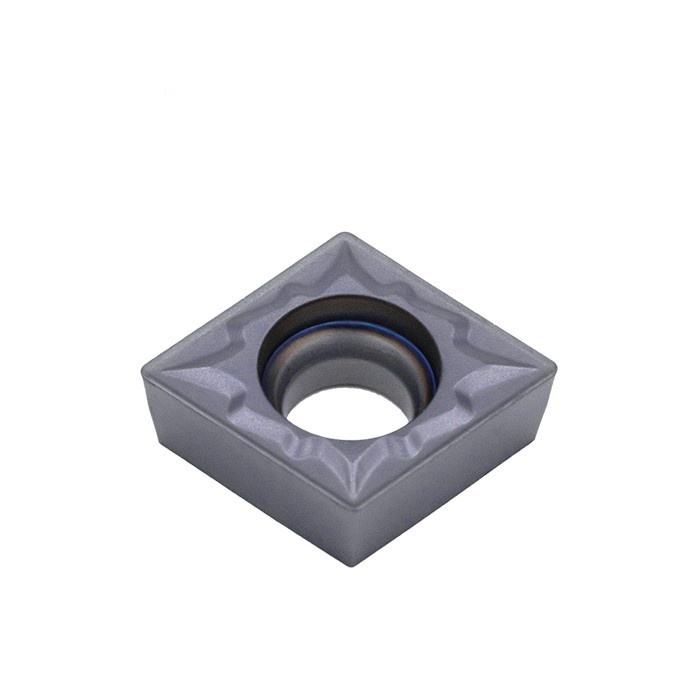

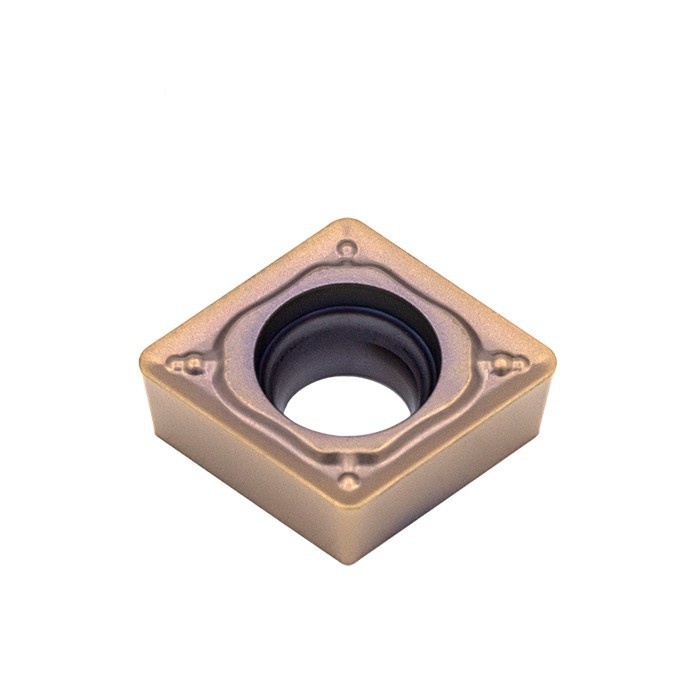

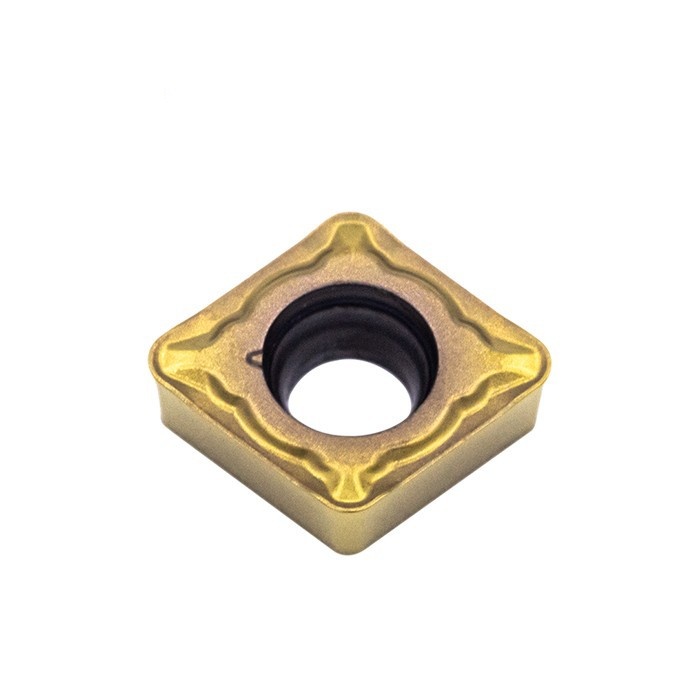

CCMT Insert for High-quality Turning and Boring Performance Details

Product Information:

CCMT carbide insert is a 80°diamond with a 7° relief. The center hole is a 40°-60° single countersink, and a single-sided chip breaker. It has higher safety and reliability for end face machining under heavy duty interrupted cutting, vibration and unstable conditions, and is an ideal tool for machining work piece surfaces in harsh conditions. In addition, the CCMT has the advantages of high accuracy, wear resistance, corrosion resistance, long service life.

Specifications:

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1525 | VY1010 |

General Semi Finishing | CCMT060204-JW | 0.40-2.10 | 0.05-0.18 | • | O | • |

| O | O | • |

| O | O |

|

CCMT060208-JW | 0.80-2.10 | 0.10-0.35 | • | O | • |

| O | O | • |

| O | O |

|

CCMT09T304-JW | 0.40-3.80 | 0.05-0.18 | • | O | • |

| O | O | • |

| O | O |

|

CCMT09T308-JW | 0.80-3.20 | 0.10-0.35 | • | O | • |

| O | O | • |

| O | O |

|

CCMT120404-JW | 0.40-4.30 | 0.05-0.18 | • | O | • |

| O | O | • |

| O | O |

|

CCMT120408-JW | 0.80-4.30 | 0.10-0.35 | • | O | • |

| O | O | • |

| O | O |

|

CCMT120412-JW | 1.20-4.30 | 0.15-0.55 | • | O | • |

| O | O | • |

| O | O |

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1525 | VY1010 |

M Finishing | CCMT060204-MM | 0.30-1.60 | 0.05-0.15 | • |

|

|

|

|

|

| O |

| • | O |

|

CCMT060208-MM | 0.60-1.60 | 0.10-0.30 | • |

|

|

|

|

|

| O |

| • | O |

|

CCMT09T304-MM | 0.30-2.20 | 0.05-0.15 | • |

|

|

|

|

|

| O |

| • | O |

|

CCMT09T308-MM | 0.60-2.40 | 0.10-0.30 | • |

|

|

|

|

|

| O |

| • | O |

|

• : Recommended Grade

O: Optional Grade

Application:

The CCMT is widely applied in cutting and grooving, thread turning, etc. It’s an good ideal choice for roughing.semi-finishing.finishing.general machining of steel. stainless steel and cast iron.

FAQ:

What is tool insert?

Inserts are removable cutting tips, which means they are not brazed or welded to the tool body. They are usually indexable, meaning that they can be exchanged, and often also rotated or flipped, without disturbing the overall geometry of the tool (effective diameter, tool length offset, etc.).

What does indexable tooling mean?

Indexable tools are predominantly made of inserts or tips, where the cutting edge is a replaceable shaped piece which is welded or clamped on to a tool body. These are generally used for turning, milling and hole-making operations.

Our Company

Package Shipment