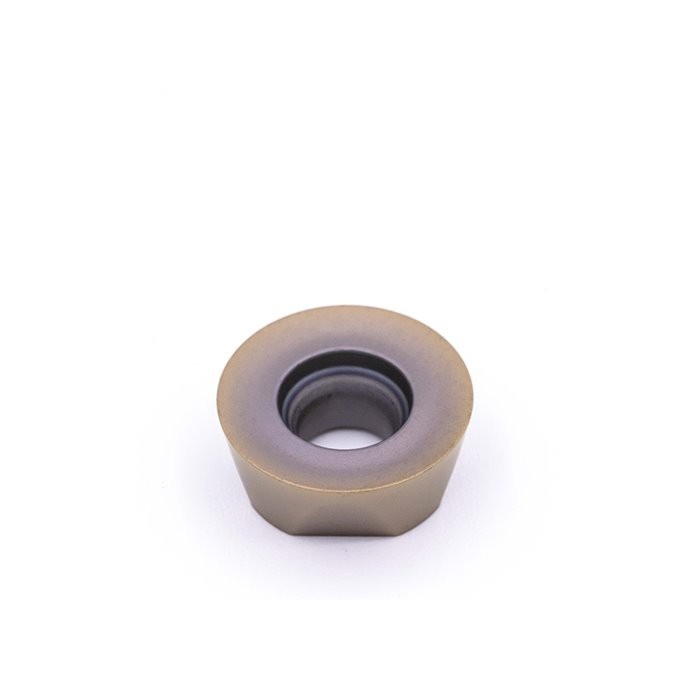

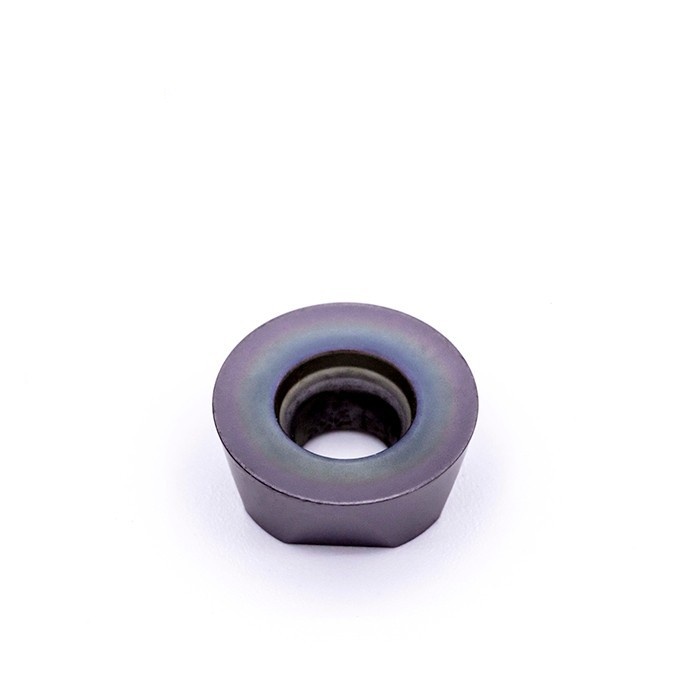

RPMT Insert for High-feed Milling and Roughing Applications Details

Product Information:

Profile milling is a common milling operation.

RPMT insert is one kind of profile milling insert with strong cutting edges, best reliability and long endurance.

R - Round shape of turning insert.

P - Insert with clearance under main cutting edge (11°).

M - Tolerances and dimensions of carbide turning insert.

T - Hole through insert and single sided chip breaker.

Specifications:

|

Type

|

Ap

(mm)

|

Fn

(mm/rev)

|

CVD

|

PVD

|

|

VT3020

|

VT3040

|

VT1025

|

VT1325

|

VT1525

|

VT1328

|

VY1010

|

VY1520

|

VY1525

|

VY1028

|

VY1330

|

|

RPMT08T2MOE-JSM

|

1.00-1.30

|

0.05-0.25

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT10T3MOE-JSM

|

1.50-4.00

|

0.05-0.30

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT1204MOE-JSM

|

1.50-5.00

|

0.05-0.35

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT1606MOE-JSM

|

2.00-6.50

|

0.10-0.40

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT08T2MO-GM

|

1.50-4.00

|

0.10-0.30

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT10T3MO-GM

|

1.80-5.00

|

0.10-0.50

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT1204MO-GM

|

2.00-6.50

|

0.10-0.50

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT08T2MO

|

1.5-4.0

|

0.1-0.3

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT10T3MO

|

1.8-5.0

|

0.1-0.5

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

|

RPMT1204MO

|

2-6.5

|

0.1-0.5

|

|

|

•

|

•

|

O

|

O

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application

Round inserts and concepts with radius are milling cutters used for roughing and semi-roughing while ball nose end mills are milling cutters used for finishing and super-finishing.

Recommend for roughing, semi-roughing, semi-finishing and finishing of steel, stainless steel, cast iron and super alloys.

FAQ:

What is a profile in machining?

Profile milling is a type of milling process, usually used to semi-finish or finish the vertical or slanted surfaces, including multi-axis milling of convex and concave shapes in two or three dimensions. Profile milling CNC Sequence is a 2.5 axis sequence.

How is milling done?

The milling process is removing the materials by performing many separate and small cuts. It is accomplished by using a cutter with many teeth, spinning the cutter at a high speed, or advancing the material through the cutter slowly.

Our Company

Package Shipment