Durable Cemented Carbide Insert for Extended Tool Life Details

Product Information:

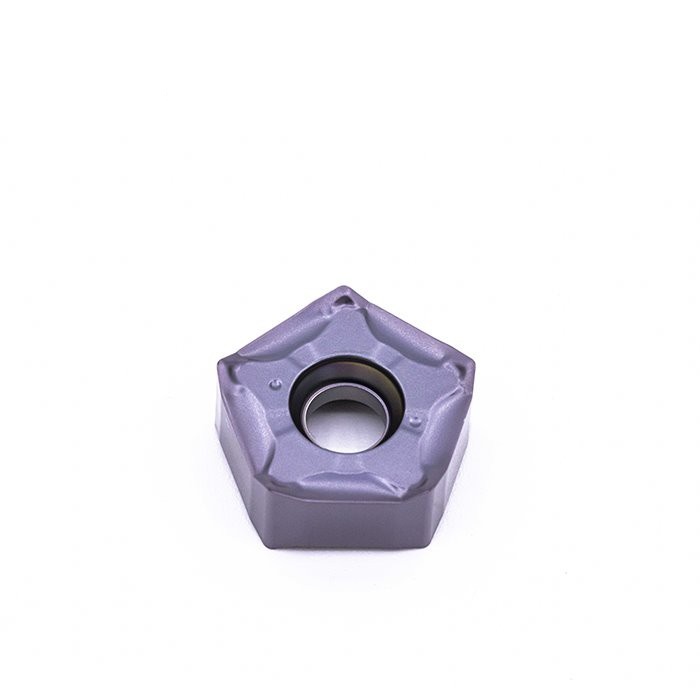

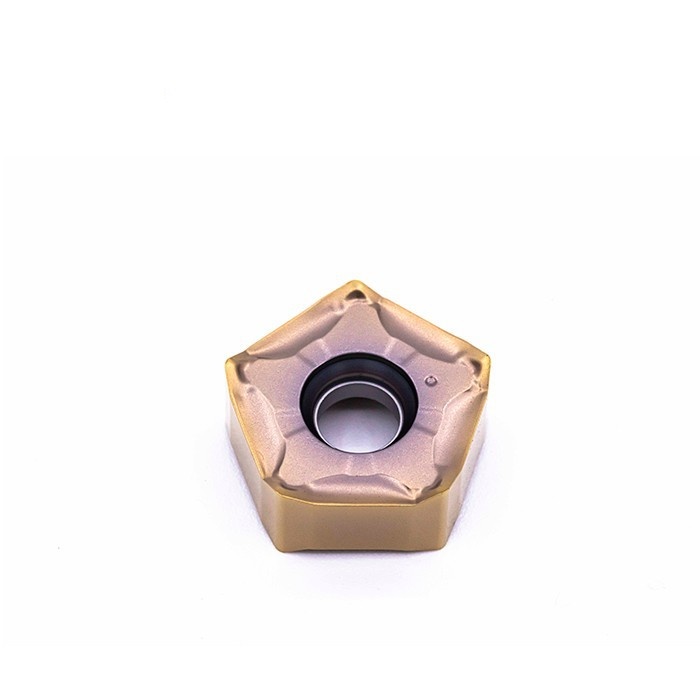

Cost-efficiency with Process Reliability Tungsten carbide milling Inserts PNMU. face milling insert.PNMU insert is one type of face milling inserts. This insert is mainly used for machining plane. The cutting edge structure with good balance between sharpness and strength, and has the function of collapse resistance and reduction of tangential resistance. This product also has advantages of stable performance and long service life.

Application:

Recommended for different purposes and applications of face milling, Suitable for machining

steel, stainless steel and cast iron.

FAQ:

What is the use of coated tungsten carbide?

The tungsten carbide is to create tools for machining. The carbide with abrasion-resistance and heat-resistance of the material. Widely use for machining steel.stainless steel.cast iron and high-temperature alloy.non-ferrous materials.

What is a milling insert?

Milling inserts are used to machine tough some of the toughest materials.Such as steel, stainless steel, cast iron, non-ferrous materials.

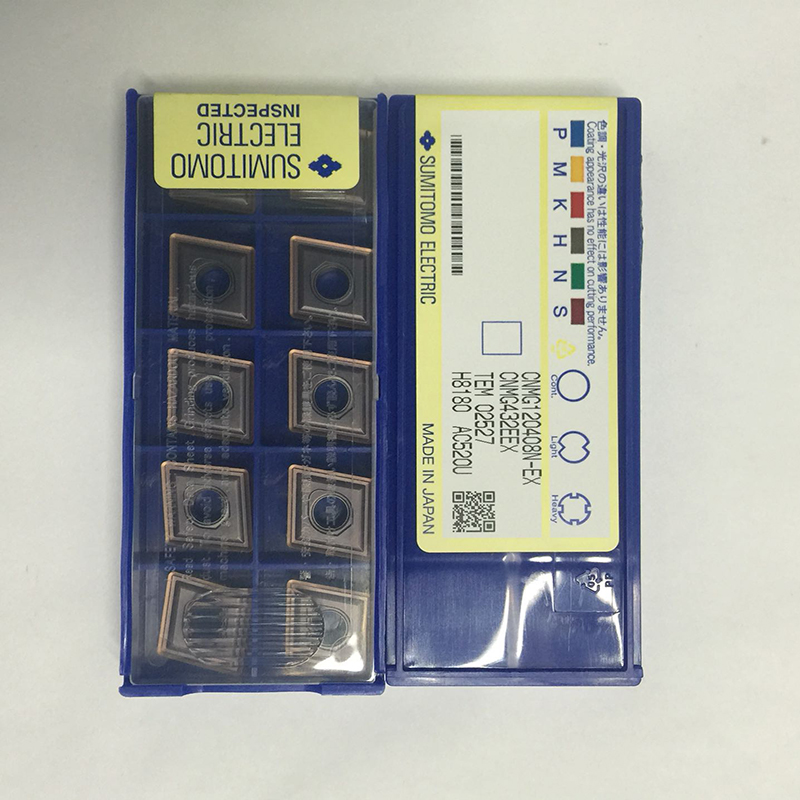

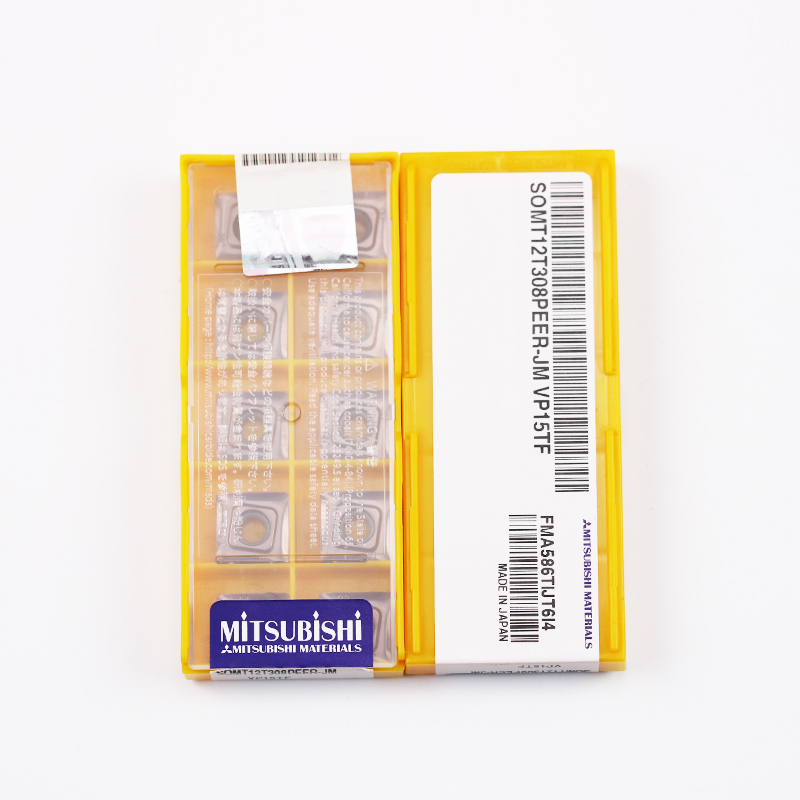

Our Company

Package Shipment