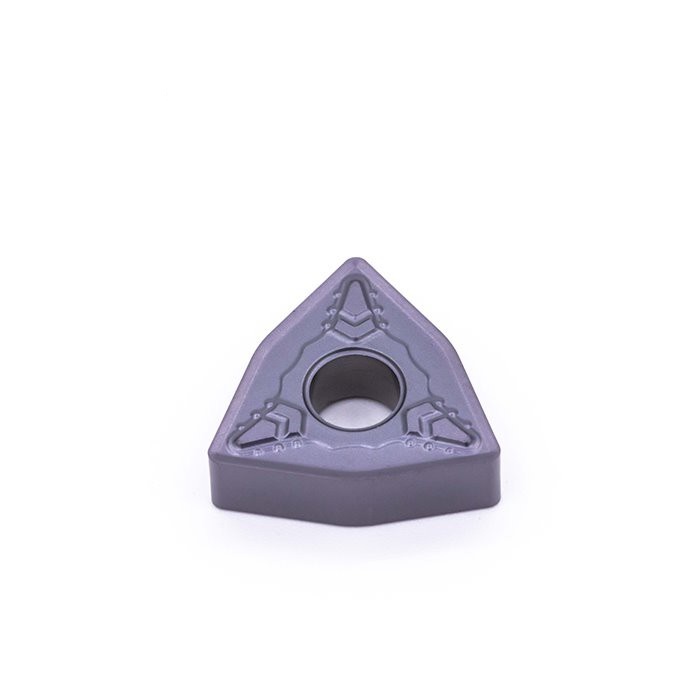

High-performance EDJ Grooving Insert for Improved Cutting Efficiency Details

Product Information:

Grooving tool is usually a carbide insert mounted in a special tool holder, similar to any other tool. Designs of grooving inserts vary, from a single tip, to an insert with multiple tips. Inserts are manufactured to nominal sizes. Multi tip insert grooving tools are used to decrease costs and increase productivity.First choice for most applications.High resistant against heat and plastic deformation.Large assortment, available in all geometries and widths

Application:

Suitable for parting, grooving, and turning. Easy machining and unobstructed chip flow lead to improved surface quality. It is a universal chip breaker for general machining of steel, stainless steel, and cast iron.

FAQ:

What are the factors are important in parting and grooving?

In parting and grooving, process security and productivity are two important aspects. With the correct setup and choice of tools, there are many difficulties that can be avoided when parting-off.

What are the tools used for grooving?

Grooving tool is usually a carbide insert mounted in a special tool holder, similar to any other tool. Designs of grooving inserts vary, from a single tip, to an insert with multiple tips. Inserts are manufactured to nominal sizes. Multi tip insert grooving tools are used to decrease costs and increase productivity.

Our Company

Package Shipment