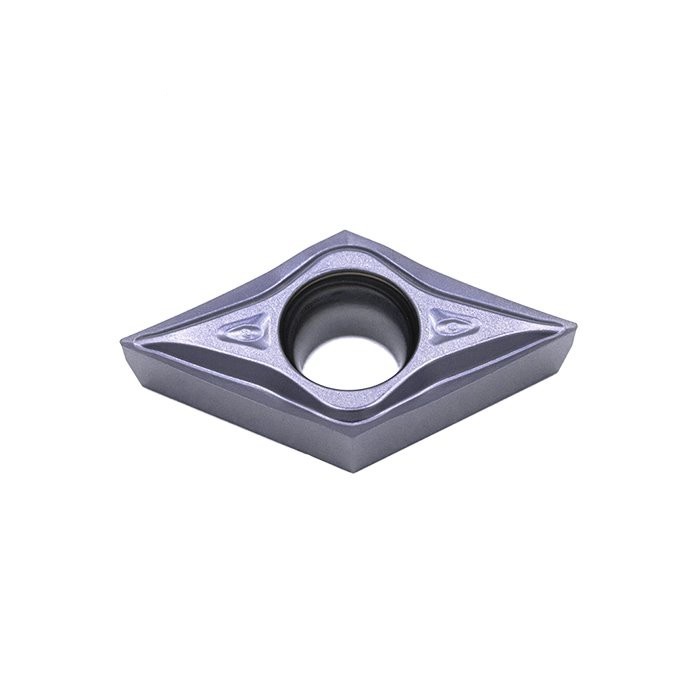

XNMU Insert for Superior Surface Finish and Extended Tool Life Details

Product Information:

XNMU milling insert with 0 degree clearance angle. Double-sided inserts with economical 14 cutting edges for steel and cast iron milling.Inserts available in multiple grades.0° negative relief angle for insert strength and durability.Coolant thru capable.Very strong and durable face mills.

Suitable for multiple materials.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

XNMU070508-MM | 0.2-3.0 | 0.05-0.2 |

|

| • | • | O | O |

|

|

|

|

|

XNMU070508AN-GR | 0.2-3.0 | 0.05-0.2 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

Application for high productivity finish and semi-finish face milling of stainless steels, steels and alloy steels.

FAQ:

What is successful face milling?

Face milling is the most common milling operation, and can be performed using a wide range of different tools. Cutters with a 45º entering angle are most frequently used, but round insert cutters, square shoulder cutters, and side and face mills are also used for certain conditions. Be sure to choose the right cutter for the operation, for optimal productivity (see information on choice of tools below).

What is successful high-feed milling?

When machining aluminum, and sometimes when machining cast iron with CBN or ceramic inserts, cutting speeds of more than 1,000 m/min can be used, which result in a very high table feed, vf. This type of machining is called High-Speed Machining (HSM).

In milling short-chipping materials, such as gray cast iron, a face milling cutter with an extra-close pitch can be used, resulting in high table feed. In HRSA materials where cutting speed is normally low, an extra-close pitch results in a high table feed.

Our Company

Package Shipment