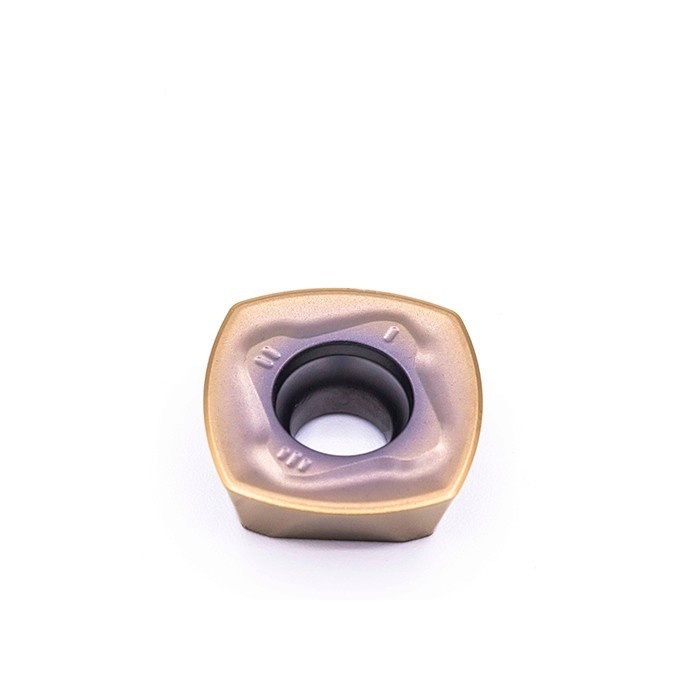

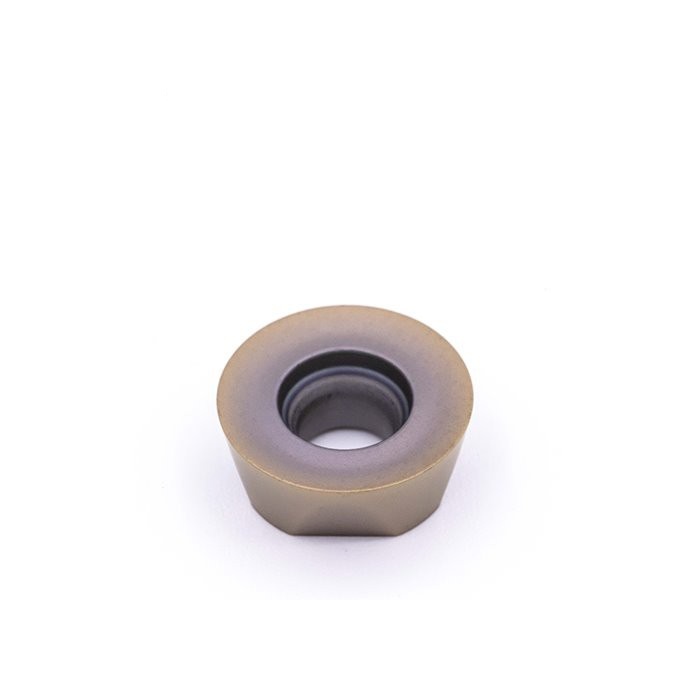

SDMT Insert: Stability and Efficiency for Demanding Machining Needs Details

Product Information:

High feed milling is a milling method that permits up to three times faster machining than conventional methods. It pairs shallow depth of cut with high feed per tooth which gives higher metal removal rates and results in more parts being machined.High feed milling insert SDMT type with 4 edges is highly cost-effective; it has an extraordinary cutting feed rate, and the processing efficiency is 3 to 5 times higher than traditional products; the blade adopts R shape.

Specifications:

class="table" >

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

SDMT120512-GM | 0.50-2.00 | 0.60-1.20 |

|

| • | • | O | O |

|

|

|

|

|

SDMT150512-GM | 0.80-3.00 | 0.60-1.20 |

|

| • | • | O | O |

|

|

|

|

|

SDMT06T208-GH | 0.50-1.20 | 0.50-1.00 |

|

| • | • | O | O |

|

|

|

|

|

SDMT09T312-GH | 0.50-1.80 | 0.50-1.00 |

|

| • | • | O | O |

|

|

|

|

|

SDMT120412-GH | 0.50-2.00 | 0.60-1.20 |

|

| • | • | O | O |

|

|

|

|

|

SDMT150520-GH | 0.80-3.00 | 0.60-1.20 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application

Recommend for processing steel, cast iron and other materials, mainly used in plane milling and large cavity milling.

FAQ:

What is high speed machining?

High-feed milling is a machining method that pairs shallow depth of cut with high feed rate. It can achieve a very high metal-removal rate, high-speed machining to reduce cycle time, increase tool life and productivity.

How is milling done?

The milling process is removing the materials by performing many separate and small cuts. It is accomplished by using a cutter with many teeth, spinning the cutter at a high speed, or advancing the material through the cutter slowly.

Our Company

Package Shipment