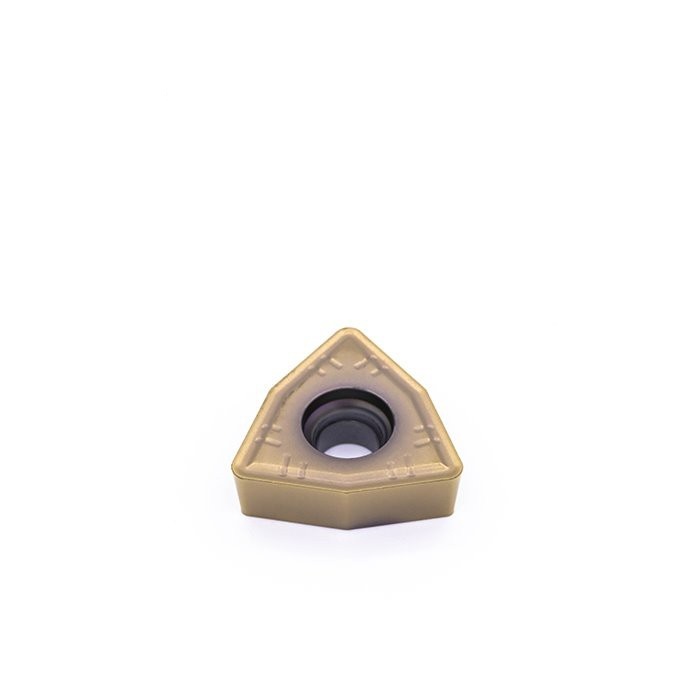

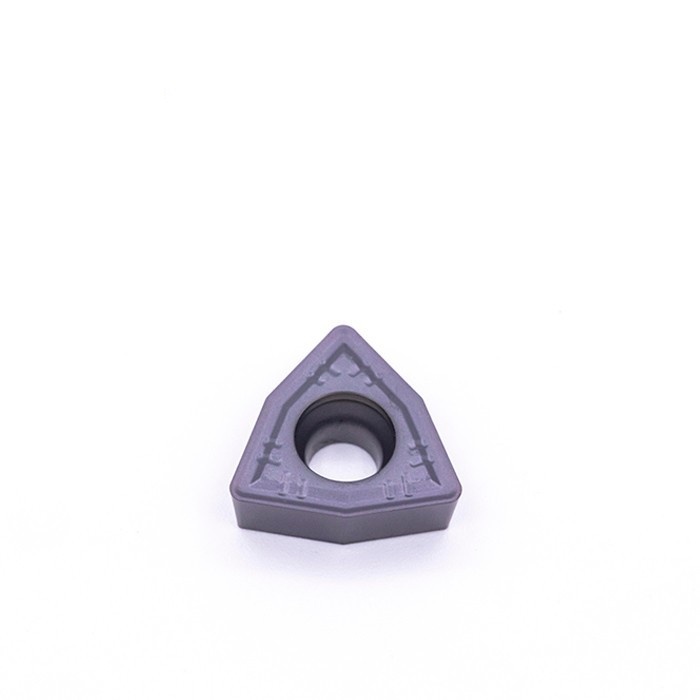

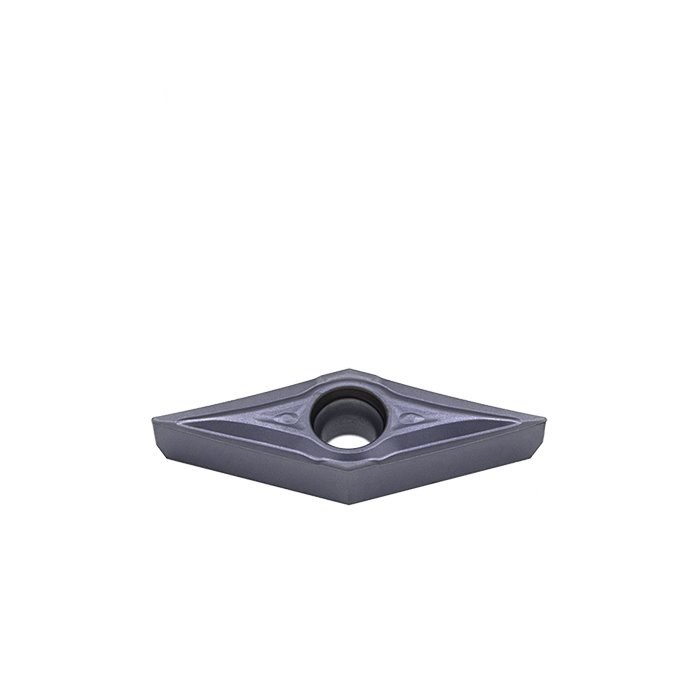

WCMT Insert for Versatile Drilling and Improved Productivity Details

Product Information:

WCMT is one kind of shallow hole indexable insert. It is power-efficient, productive.WC-type inserts are the most commonly used drill inserts in metalworking world. Indexable insert drills can be used in boring operations in order to save tool changing time. It is power-efficient, productive and reduces demands on the machine tool spindle as the main cutting forces are directed axially along the spindle.

Specifications:

| Type | Boring Range (mm) | Size | Application | Grade |

L | øI.C | S | ød | r | PVD

|

VT1025 | VT1325 |

WCMT030208-JW | 16-20 | 3.8 | 5.56 | 2.38 | 2.8 | 0.8 | Semi-finishing | • | • |

WCMT040208-JW | 21-25 | 4.3 | 6.35 | 2.38 | 3.1 | 0.8 | • | • |

WCMT050308-JW | 26-30 | 5.4 | 7.94 | 3.18 | 3.2 | 0.8 | • | • |

WCMT06T308-JW | 31-41 | 6.5 | 9.53 | 3.97 | 3.7 | 0.8 | • | • |

WCMT080412-JW | 42-58 | 8.7 | 12.7 | 4.76 | 4.3 | 1.2 | • | • |

Application

Application for hole machining in various materials. Steel, stainless steel and cast iron.

FAQ:

What is an indexable drill bit?

Indexable drill bits have a fluted body that accepts replaceable cutting inserts to form a cutting edge for drilling holes into workpieces. The inserts can be rotated (indexed) to expose a fresh cutting edge when the old one dulls.

What are thread inserts used for?

The threaded insert is a sleeve with a threaded interior that can accept a bolt or threaded fastener. The thread insert can be made of different materials with different dimensions, and come in different configurations or tooling.

Our Company

Package Shipment