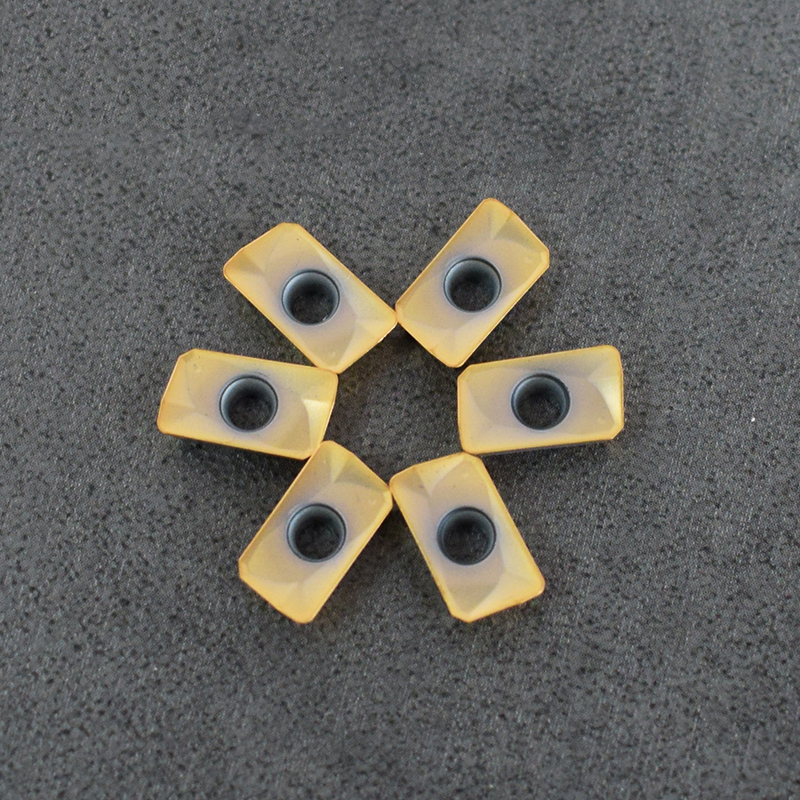

ERMN Profile Grooving Insert for Machining Complex Profiles with Accuracy Details

Product Information:

High surface finish factor, good abrasion resistance. High precision, new coating technology. Adopt imported technology to process, the overall hardness is stronger, and the service life of the blade is longer.

Specifications:

| Type | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4225 | VT4235 | VT4315 | VT4325 | VT1025 | VT1824 | VT1825 | VT1528 | VY1010 | VY1525 |

ERMN300-T | 0.05-0.18 |

|

|

|

| • | O |

| • |

|

|

|

ERMN400-T | 0.07-0.25 |

|

|

|

| • | O |

| • |

|

|

|

ERMN500-T | 0.08-0.3 |

|

|

|

| • | O |

| • |

|

|

|

ERMN600-T | 0.09-0.35 |

|

|

|

| • | O |

| • |

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

When a cutting edge becomes dull, you just need to rotate the insert in the holder to use the sharp edge. It is coated, providing much longer tool life than uncoated inserts.

FAQ:

What is the grooving process?

The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. The groove shape, or at least a significant part of it, will be in the shape of the cutting tool. Grooving tools are also used for a variety of special machining operations.

Our Company

Package Shipment