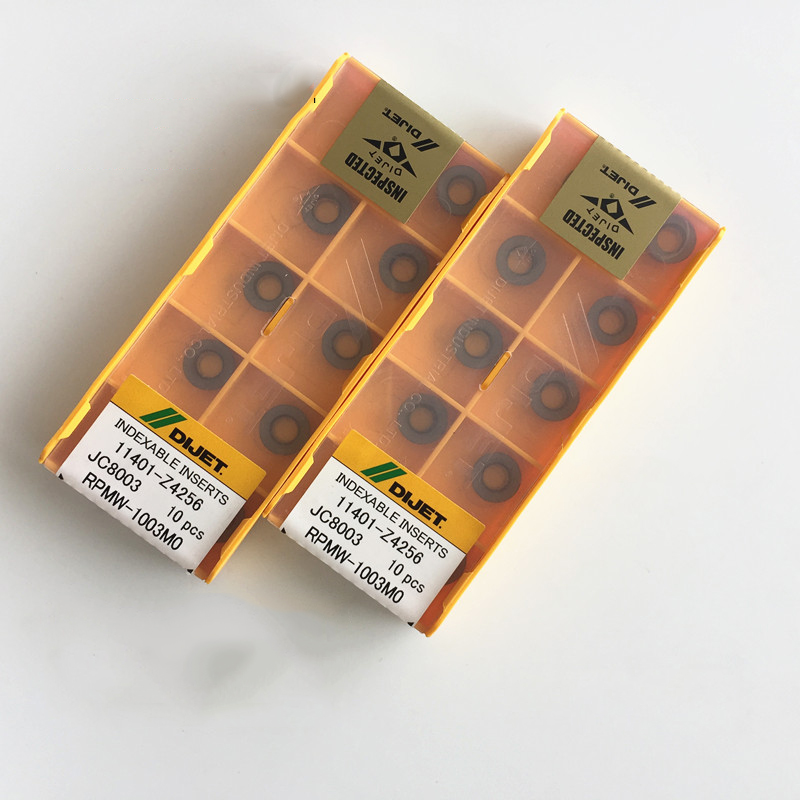

SOMT Insert for Precise and Smooth Machining Results Details

Product Information:

High-feed milling is a machining method that pairs shallow depth of cut (DOC) with high feed rate up to 2.0 mm per tooth. This combination maximizes the amount of metal being removed from a part and increases the number of finished parts in a given time.High feed milling insert SOMT type with 4 edges is highly economical; A tough submicron substrate, improved TiAlN PVD coated grade for better chip flow. It has an extraordinary cutting feed rate. Excellent notch wear and built-up edge resistance.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

SOMT100420ER-GM | 0.10-1.20 | 0.20-2.00 |

|

| • | • | O | O |

|

|

|

|

|

SOMT140520ER-GH | 0.50-2.00 | 0.42-2.00 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application

Designed for machining heat resistant alloys, austenitic stainless steel, hard alloys and carbon steel at medium to high cutting speeds, interrupted cut and unfavorable conditions. Application for plane machining, step machining, grooving machining and cavity machining.

FAQ:

What is high speed machining?

High-feed milling is a machining method that pairs shallow depth of cut with high feed rate. It can achieve a very high metal-removal rate, high-speed machining to reduce cycle time, increase tool life and productivity.

What milling method is generally recommended?

Down milling is generally recommended. With the down milling method, the burnishing effect can be avoided, resulting in less heat & minimal work-hardening tendency.

Our Company

Package Shipment