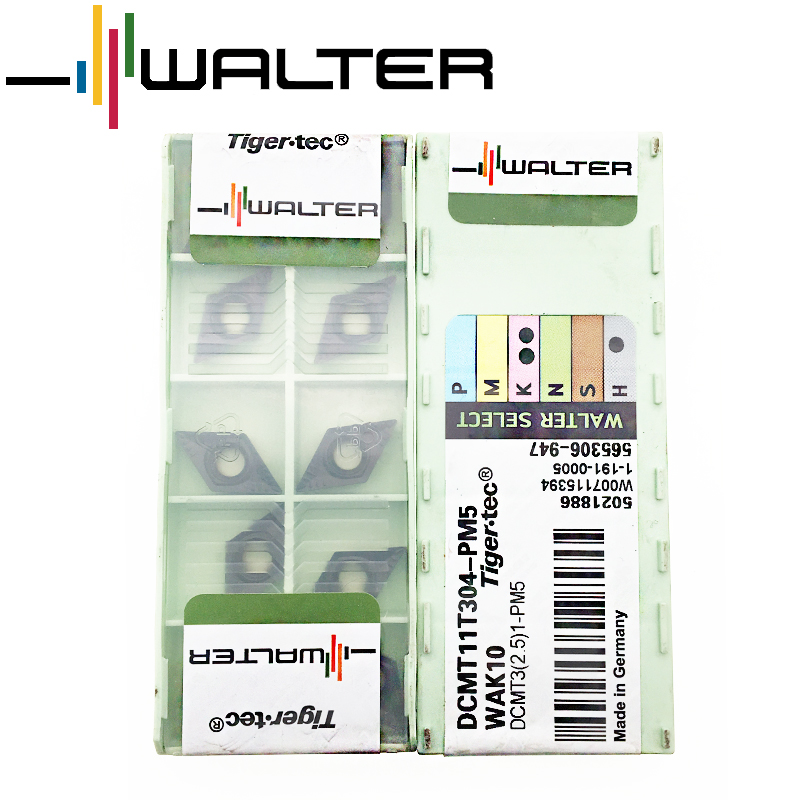

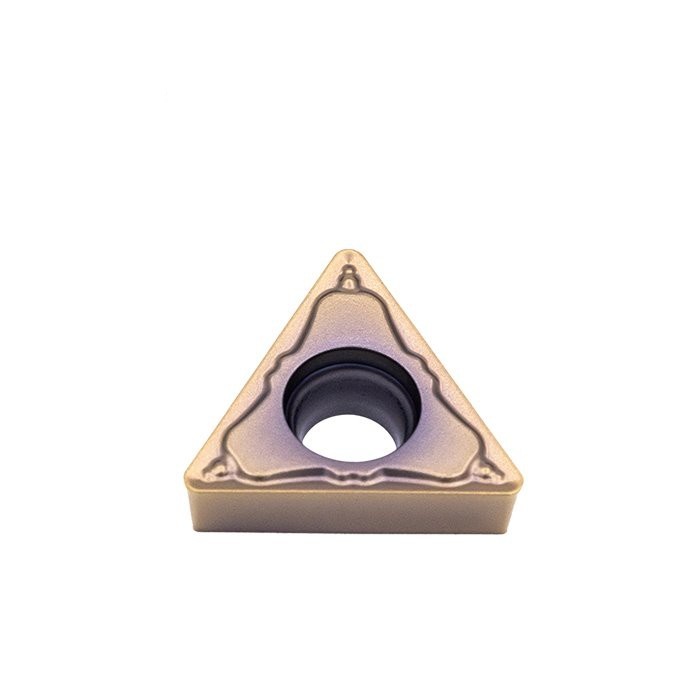

Walter Tungsten Carbide Inserts Metal Cutting Tools DCMT11T304-PM5 WAK10 Details

Specifications Details:

Model | DCMT11T304-PM5 WAK10 |

Brand Name | WALTER |

Place of Origin | Germany |

Coating | PVD CVD |

Processing Material | STEEL/STAINLESS STEEL/CASTIRON |

Package | original plastic box |

MOQ | 10PCS |

Application | turning work on metal material |

Delivery time | Short |

Transport | TNT/DHL/UPS/FEDEX/EMS/ARAMEX/BY AIR/BY SEA |

Payment | Bank transfer TT/ Paypal /ALIBABA |

Packing&Shipping:

Packaing:10 pcs/plastic box, then by carton;

Shipping method: by air or by sea. We have a long-term cooperation with DHL,Fedex and UPS logistics company,and often get special discount about the freight charge.

Delivery time:Short;

Price terms:EXW, FOB, CFR, CIF.

Payment terms: T/T, Paypal, Escrow, L/C, Western Union.

Service:

Our engineers can help to design technical plan for CNC cutting machine cutting tools assembly, and offer after-sales service professionally.

Main Export Markets:

1).Eastern Europe

2).America

3).Mid East

4).Africa

5).Asia

6).Western Europe

7)Australia

Primary Advantages:

1).Competitive Prices

2).Good Performance

3).Short Delivery Time

4).Quality Controlled

5).Small Orders Acceptable

Main famous brands:

Korloy, Sumitomo,Tungaloy,Mitsubishi, Kyocera, Iscar, SECO, SANDVIK, WALTER, Dijet, Kennametal, GUHRING, YG, YAMAWA, Hitachi, Valenite, Walter, Taegutec, ZCC.CT, OSG, LINKS, Lamina,Vargus, etc.

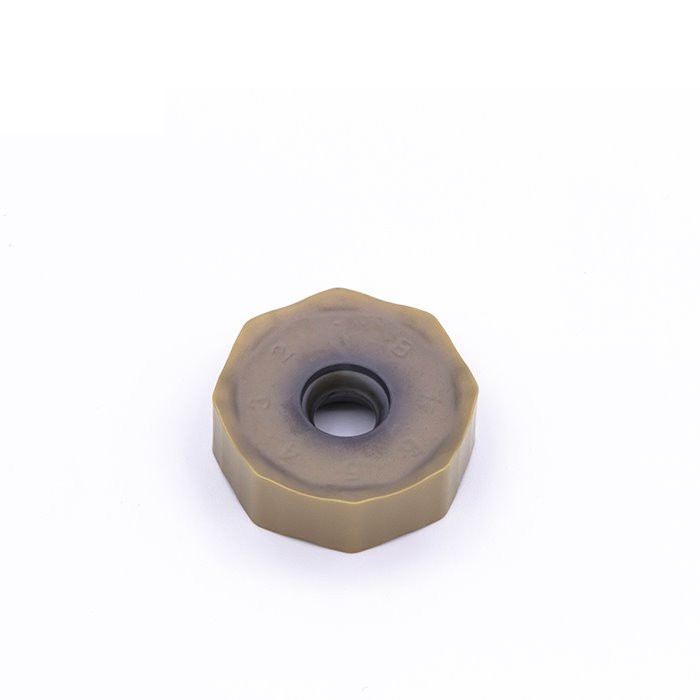

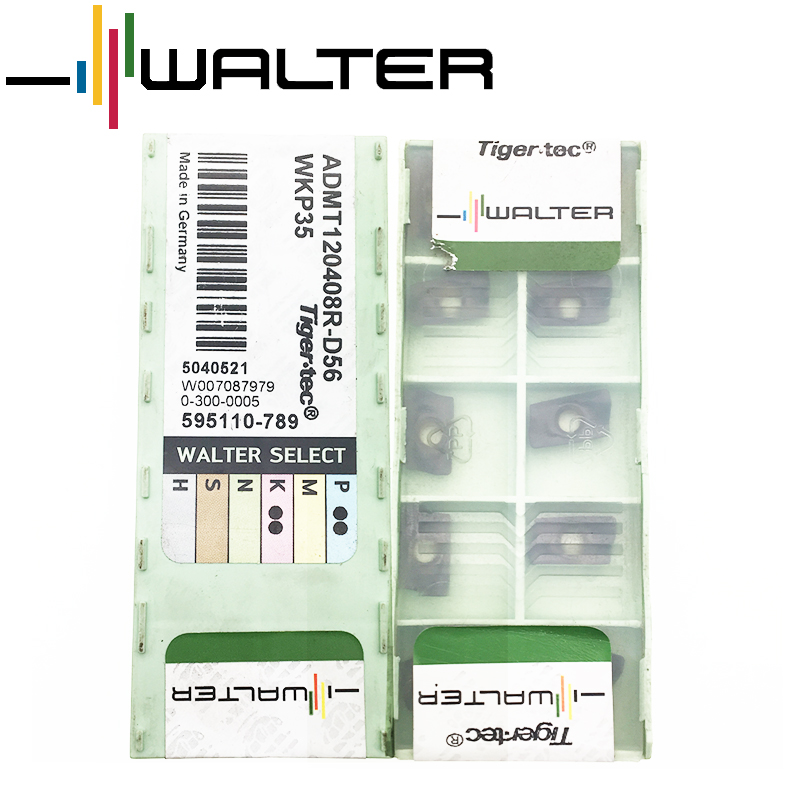

Walter carbide inserts

| CCMT120404-PF4 WSM20 | SDNT090308 WTL71 |

| CCMT120404-PM5 WAK20 | SNGX1205ANN-F57 WKK25 |

| CCMT120408-E47 WPP20 | SNGX1205ANN-F57 WKP25 |

| CCMT120408-PF4 WSM10 | SNGX1205ANN-F57 WSP45 |

| CCMT120408-PM5 WAK10 | SNGX1205ENN-F27 WKP25 |

| CCMT120408-PM5 WAK30 | SNGX1205ENN-F27 WKP25S |

| CCMT120408-PM5 WPP10 | SNGX1205ENN-F57 WKK25 |

| CCMT120408-PM5 WPP20 | SNGX1205ENN-F57 WKP25 |

| CCMT120408-PS5 WSM20 | SNGX1205ENN-F67 WSM35S |

| CNMG120404-NF3 WPP10 | SNMA120416-RK7 WKK20S |

| CNMG120404-NM4 WAM30 | SNMG120408-NM6 WPP20 |

| CNMG120404-NM4 WAP20 | SNMG150612-NM4 WAP20 |

| CNMG120404-NM4 WSM30 | SNMG150616-NM5 WAK10 |

| CNMG120408-NM4 WAM30 | SNMG150616-NRS WSM20 |

| CNMG120408-NM4 WSM30 | SNMX120512-D27 WKK25 |

| CNMG120408-NM5 WAK10 | SNMX120512-F12 WKP25 |

| CNMG120408-NM5 WAK20 | SNMX120512-F27 WKP25 |

| CNMG120408-NR4 MSM10 | SNMX120512-F27 WKP35 |

| CNMG120408-NR4 WSM30 | SNMX120512-F57 WKK25 |

| CNMG120412-MP5 WPP30S | SNMX120512-F57 WKP25 |

| CNMG160612-NRS WSM20 | SNMX120512-F57 WKP35 |

| CNMG190612-NM5 WAK20 | SNMX120512-F57 WKP35S |

| CNMG190612-NM6 WPP20 | SNMX120512-F57 WSM35 |

| CNMU160812-D57T WKP35 | SNMX120512-F67 WKP25 |

| DCMT070204-PF4 WSM30 | SNMX120512-F67 WSM35 |

| DCMT11T304-PF4 WPP10 | SNMX1205ANN WXH15 |

| DCMT11T304-PF4 WSM30 | SNMX1205ANN-F57 WKP25 |

| DCMT11T304-PM5 WAK10 | SNMX1205ANN-F57 WKP35 |

| DCMT11T304-PM5 WPP20 | SNMX1205ANN-F67 WAK15 |

| DCMT11T308-PF4 WPP20 | SNMX1205ANN-F67 WKP25 |

| DCMT11T308-PM5 WPP30 | SPFN1204EDN WKP25 |

| DNMG150608-NM4 WMP20S | SPGT1204AEN-K88 WK10 |

Our Company

Package Shipment