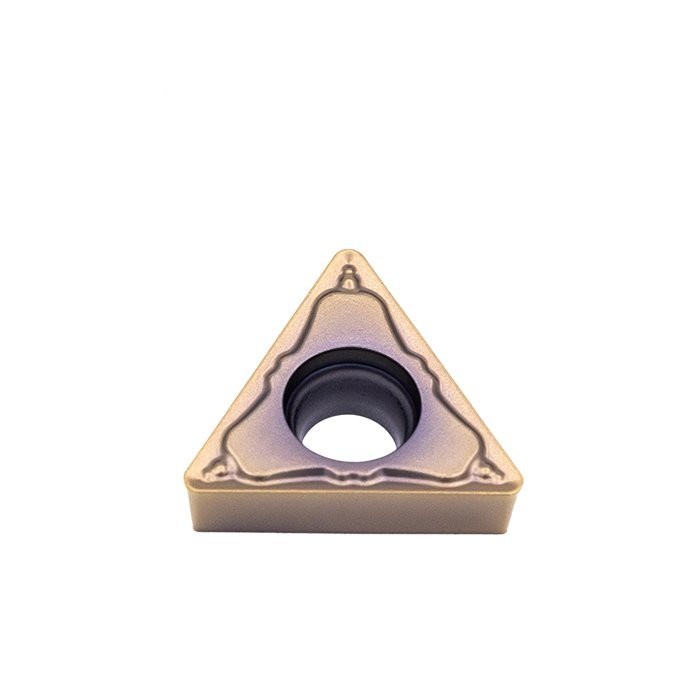

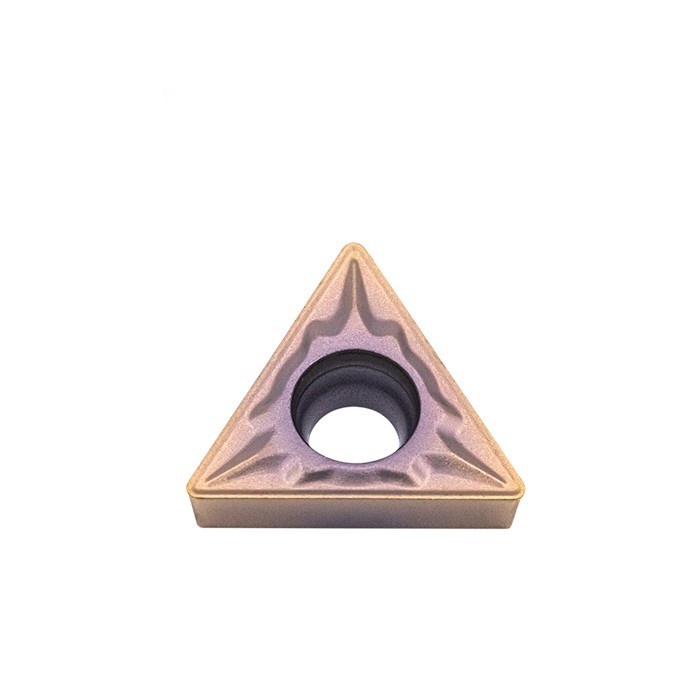

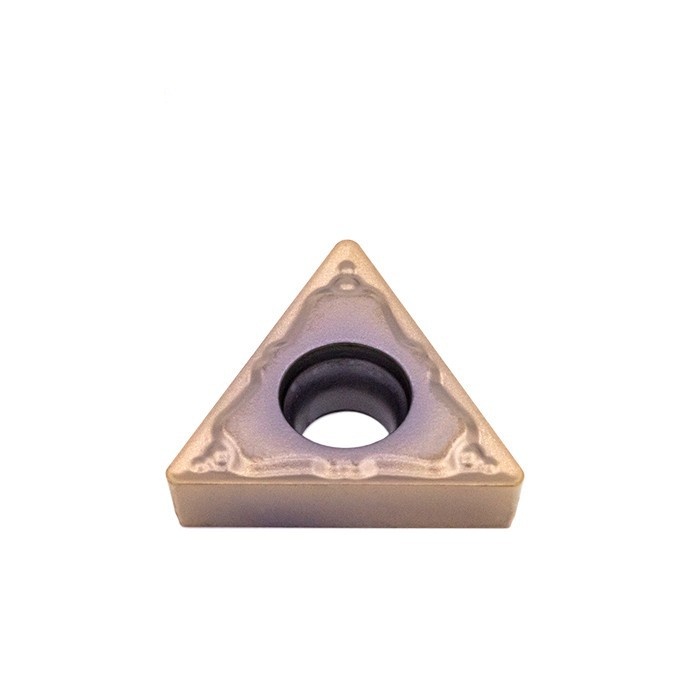

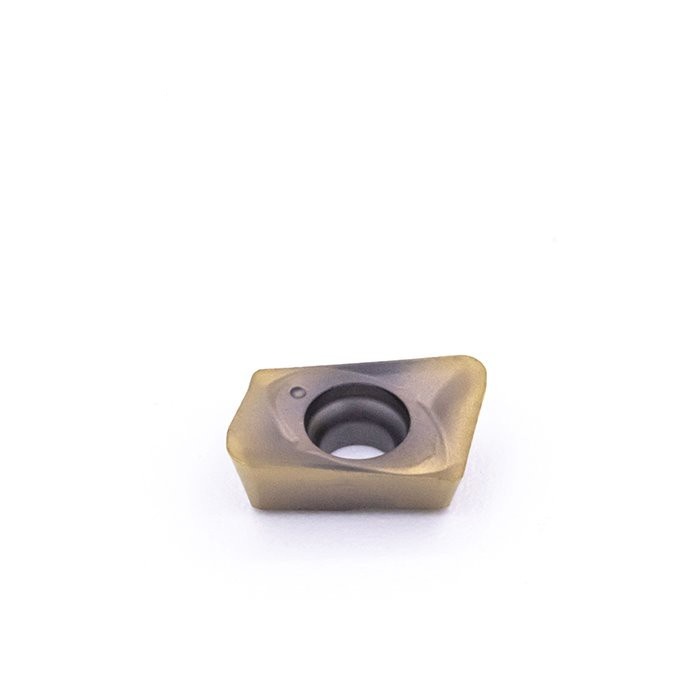

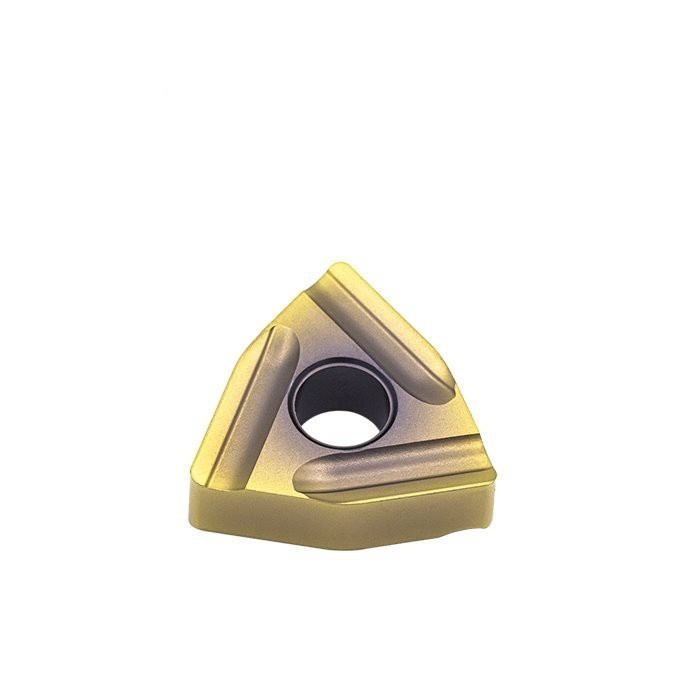

TCMT Insert for Versatile Turning, Boring, and Finishing Applications Details

Product Information:

TCMT carbide insert is a 60°triangle with a 7°relief. The center hole is a 40°-60° single countersink, and there is a single-sided chip breaker. It has an inscribed circle (IC) of 0.25" (1/4"), a thickness of 0.094" (3/32"), and a corner (nose) radius of 0.0156" (1/64").

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4335 | VT1025 | VT1525 | VT1825 | VT1828 | VY1010 | VY1525 |

TCMT090204-GM | 0.40-2.90 | 0.05-0.20 | • | O | • |

| O | O |

| • | O |

| O |

TCMT090208-GM | 0.80-2.90 | 0.10-0.35 | • | O | • |

| O | O |

| • | O |

| O |

TCMT110204-GM | 0.40-3.30 | 0.05-0.20 | • | O | • |

| O | O |

| • | O |

| O |

TCMT110208-GM | 0.80-3.30 | 0.10-0.35 | • | O | • |

| O | O |

| • | O |

| O |

TCMT110212-GM | 1.20-3.30 | 0.15-0.55 | • | O | • |

| O | O |

| • | O |

| O |

TCMT16T304-GM | 0.40-4.90 | 0.05-0.20 | • | O | • |

| O | O |

| • | O |

| O |

TCMT16T308-GM | 0.80-4.90 | 0.10-0.35 | • | O | • |

| O | O |

| • | O |

| O |

TCMT16T312-GM | 1.20-4.90 | 0.15-0.55 | • | O | • |

| O | O |

| • | O |

| O |

• : Recommended Grade

O: Optional Grade

| Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1525 | VT1824 | VT1825 | VT1828 | VY1010 | VY1520 | VY1525 | VY1028 |

TCMT090204-GF | 0.30-1.80 | 0.05-0.15 |

|

|

|

|

| • | O | • |

| O | O |

|

|

TCMT090208-GF | 0.60-2.20 | 0.10-0.30 |

|

|

|

|

| • | O | • |

| O | O |

|

|

TCMT110204-GF | 0.30-2.20 | 0.05-0.15 |

|

|

|

|

| • | O | • |

| O | O |

|

|

TCMT110208-GF | 0.60-3.30 | 0.10-0.30 |

|

|

|

|

| • | O | • |

| O | O |

|

|

TCMT110212-GF | 1.20-3.30 | 0.20-0.40 |

|

|

|

|

| • | O | • |

| O | O |

|

|

TCMT16T304-GF | 0.30-3.30 | 0.05-0.15 |

|

|

|

|

| • | O | • |

| O | O |

|

|

TCMT16T308-GF | 0.60-3.30 | 0.10-0.30 |

|

|

|

|

| • | O | • |

| O | O |

|

|

TCMT16T312-GF | 1.20-3.30 | 0.10-0.40 |

|

|

|

|

| • | O | • |

| O | O |

|

|

• : Recommended Grade

O: Optional Grade

Application:

TCMT Triangle Insert with Hole. Screw-On Insert. 7 degree relief angle. Single Sided Insert with GM/GF-Medium Chip breaker for semi-finishing and finishing in a variety of materials and applications.

FAQ:

What is negative and positive insert?

A negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). The illustration of the negative style insert, shows how the insert is assembled and tilted in the holder.

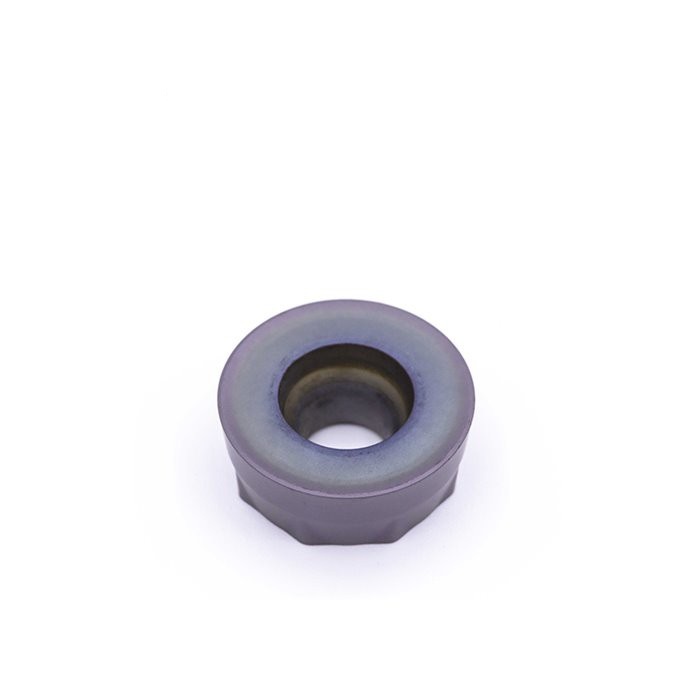

What is DNMG insert?

DNMG inserts are diamond or “D” shaped turning inserts with a 55-degree angle. They're a versatile cutting tool used for grooving, profiling, finishing, and other machining applications. Our DNMG inserts are all manufactured by Walter – a well-known producer of quality and precision cutting tools.

Our Company

Package Shipment