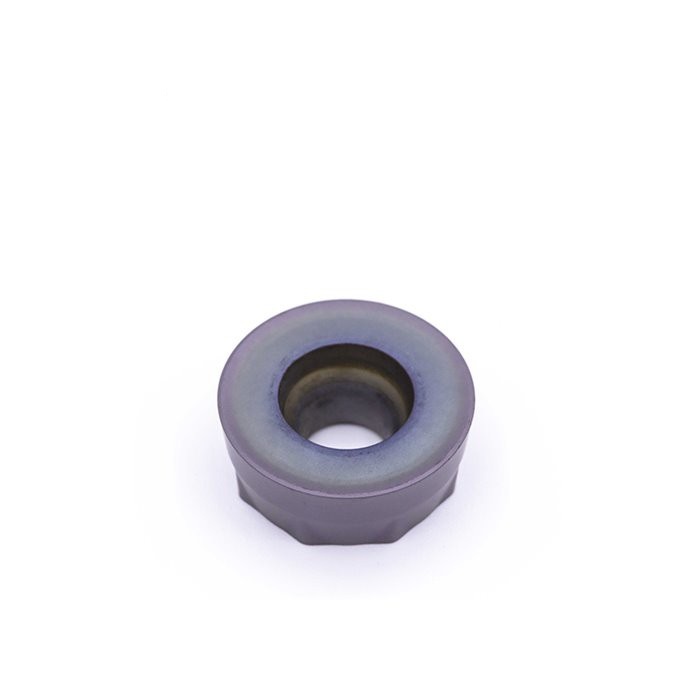

RCMT Insert: Superior Surface Finish and Extended Tool Life Guaranteed Details

Product Information:

RCMT standard carbide (with coating) turning inserts are with strong cutting edges, which provide best reliability and long endurance.

R - Round shape of turning insert

C - Insert with clearance under main cutting edge (7°).

M - Tolerances and dimensions of carbide turning insert.

T - Hole through insert and single sided chip breaker.

The R-type inserts have extra-strong cutting edge to meet the requirements for machining of curved surface of die.

Application:

Recommended for all purposes and applications, especially in milling. It mainly focuses on face milling and cavity profile milling of steel, alloy steel, stainless steel and cast iron.

FAQ:

What is Profile milling?

Profile milling is a common milling operation. Round inserts and concepts with radius are milling cutters used for roughing and semi-roughing while ball nose end mills are milling cutters used for finishing and super-finishing.

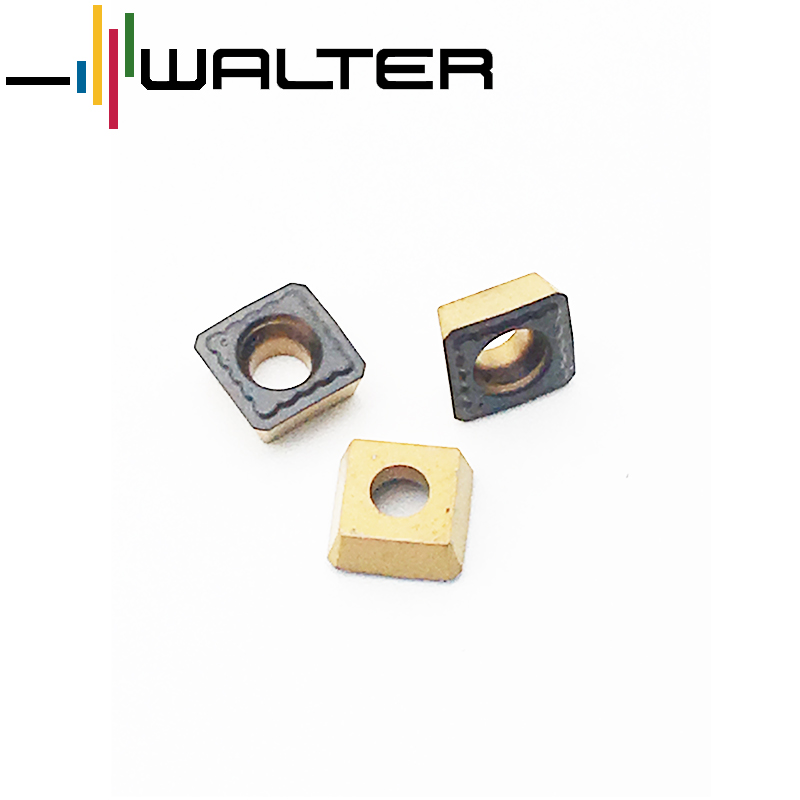

What are cemented carbide tools?

Cemented carbide consists of particles of carbide cemented into a composite by a binder metal.it is used extensively as cutting tool material, as well as other industrial applications.

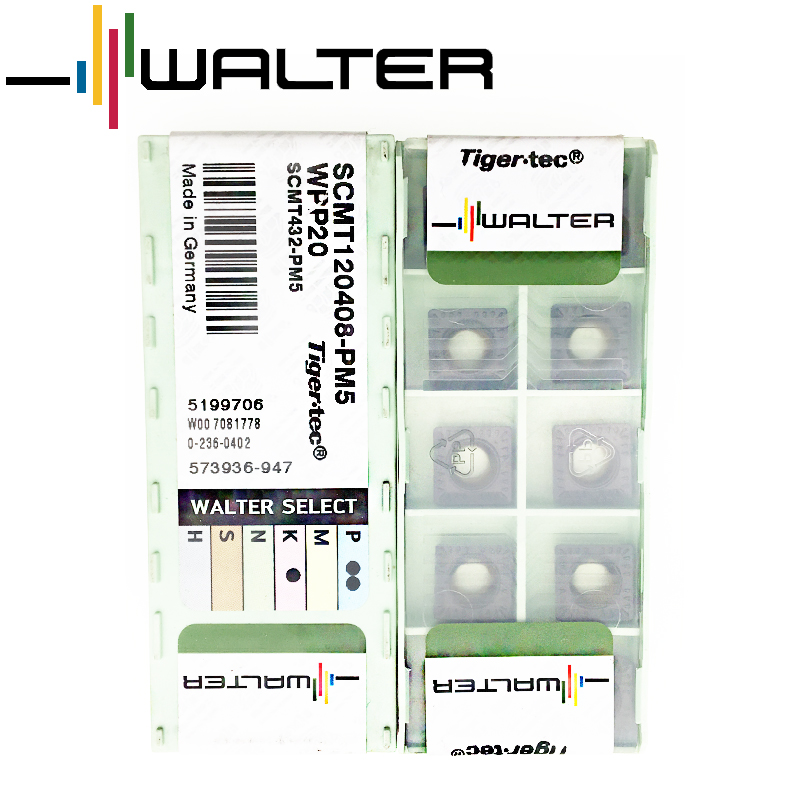

Our Company

Package Shipment