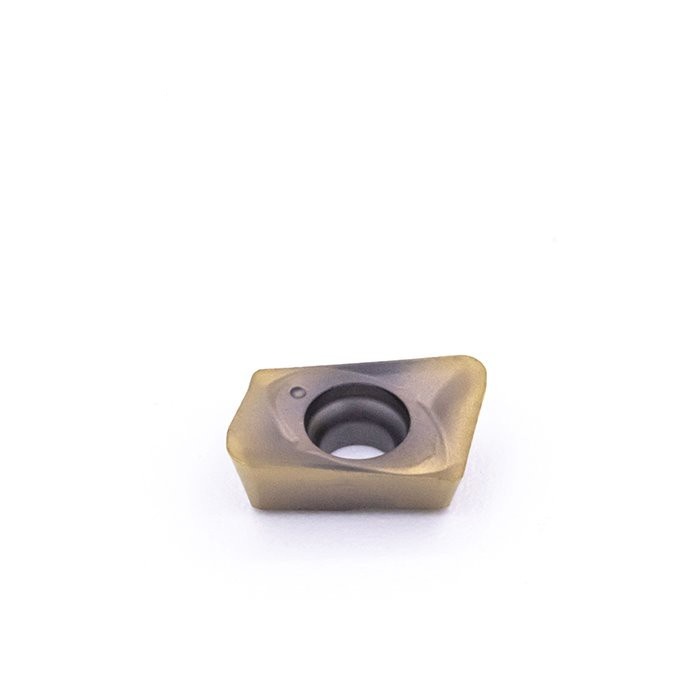

Korloy Tungsten Carbide Turning Inserts TNMG160404-HA-PC9030 Details

Product Description:

1.For steel/ stainless steel/cast iron processing

2.Excellent wear resistance and breakage resistance

3.Professional inspection and high precision

4.High precison, easy replacement, general use

| Product Name | Korloy Tungsten Carbide turning inserts TNMG160404-HA-PC9030 |

| Material | steel/stainless steel |

| Coating | CVD/PVD |

| Standard | ISO |

| Grade | PC9030 |

| OEM | Supply |

| Suitable for | Turning tool holder |

| Used | CNC Lathe machinery |

FAQ:

1. How to place an order?

1.Fill your Order List in our online Inquiry System. 2.Directly contact our salesperson by E-mail / Skype / Whats App

We will make a feedback to you ASAP after receive your order list.

2. What is your payment terms?

T/T, Paypal, Western Union, Alibaba assurance for different circumstances.

3. What’s your delivery way?

Express delivery, DHL, TNT, FEDEX , EMS, air shipping, sea shipping are available for your request.

4. How about the delivery time?

Usually delivery time is 2~3 days after receiving the advance payment. For the customized product, 7-10 days after receiving the advance payment.

Our Company

Package Shipment