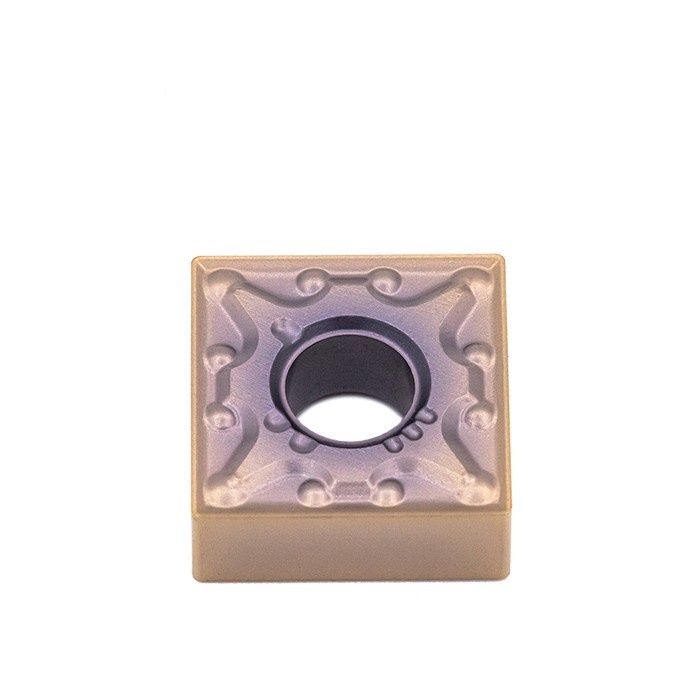

SNMG Insert for High-speed Turning and Facing Operations Details

Product Information:

Turing insert SNMG. Double-Sided 90° square inserts. 0 degree relief angle. Solid carbide tools offer long tool life and faster cutting speeds than other substrates, but are more brittle and must be used with rigid tool holding systems.Provides longer tool life than uncoated grades. Used on a wide range of materials and applications.

Specifications:

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 |

P Semi Finishing | SNMG120404-AM | 1.00-5.00 | 0.12-0.40 | • | O | • |

| O | O |

|

|

|

|

|

|

SNMG120408-AM | 1.20-5.00 | 0.15-0.55 | • | O | • |

| O | O |

|

|

|

|

|

|

SNMG120412-AM | 1.50-5.00 | 0.20-0.55 | • | O | • |

| O | O |

|

|

|

|

|

|

SNMG150612-AM | 2.00-7.00 | 0.30-0.65 | • | O | • |

| O | O |

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT4235 | VT4335 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 |

P Rough Machining | SNMG120408-AR | 2.50-6.00 | 0.25-0.70 |

|

| • | O |

|

|

|

|

|

|

|

|

SNMG120412-AR | 2.50-6.00 | 0.30-0.70 |

|

| • | O |

|

|

|

|

|

|

|

|

SNMG120416-AR | 2.50-6.00 | 0.40-0.70 |

|

| • | O |

|

|

|

|

|

|

|

|

SNMG150612-AR | 2.15-6.40 | 0.25-0.50 |

|

| • | O |

|

|

|

|

|

|

|

|

SNMG190612-AR | 2.15-6.40 | 0.25-0.50 |

|

| • | O |

|

|

|

|

|

|

|

|

SNMG190616-AR | 2.85-7.60 | 0.30-0.65 |

|

| • | O |

|

|

|

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1525 | VY1330 |

M Finishing | SNMG120404-BF | 0.25-3.20 | 0.05-0.15 |

|

|

|

|

| • | • |

| O |

| O |

|

SNMG120408-BF | 0.50-3.20 | 0.10-0.30 |

|

|

|

|

| • | • |

| O |

| O |

|

SNMG120412-BF | 0.75-3.20 | 0.15-0.45 |

|

|

|

|

| • | • |

| O |

| O |

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1525 | VY1330 |

M Semi Finishing | SNMG120404-BM | 0.30-4.20 | 0.08-0.25 |

|

|

|

|

| O | O | • | O |

| O |

|

SNMG120408-BM | 0.65-4.20 | 0.15-0.45 |

|

|

|

|

| O | O | • | O |

| O |

|

SNMG120412-BM | 0.95-4.20 | 0.25-0.65 |

|

|

|

|

| O | O | • | O |

| O |

|

SNMG150608-BM | 0.65-5.20 | 0.15-0.45 |

|

|

|

|

| O | O | • | O |

| O |

|

SNMG150612-BM | 0.95-5.20 | 0.25-0.65 |

|

|

|

|

| O | O | • | O |

| O |

|

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1325 | VY1528 | VY1330 |

M Rough Machining | SNMG120404-BR | 0.30-4.20 | 0.08-0.25 |

|

|

|

| O | O | O | • |

|

| • | O |

SNMG120408-BR | 0.65-4.20 | 0.15-0.45 |

|

|

|

| O | O | O | • |

|

| • | O |

SNMG120412-BR | 0.95-4.20 | 0.23-0.66 |

|

|

|

| O | O | O | • |

|

| • | O |

SNMG150608-BR | 0.65-5.20

| 0.15-0.44 |

|

|

|

| O | O | O | • |

|

| • | O |

SNMG150612-BR | 0.95-5.20 | 0.23-0.66 0.23-0.66 |

|

|

|

| O | O | O | • |

|

| • | O |

• : Recommended Grade

O: Optional Grade

| Application | VT3040 | Ap (mm) | Fn (mm/rev) | Grade |

| CVD |

VT3020 | VT3040 | VT3315 | VT3415 |

K Semi Finishing | SNMG120404-CM | 0.40-4.20 | 0.08-0.25 |

|

| • | O |

SNMG120408-CM | 0.80-4.20 | 0.15-0.45 |

|

| • | O |

SNMG120412-CM | 1.20-4.20 | 0.25-0.65 |

|

| • | O |

• : Recommended Grade

O: Optional Grade

| Application | Type | Ap (mm) | Fn (mm/rev) | Grade |

| CVD | PVD |

VT4215 | VT4315 | VT4225 | VT4325 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1030 |

S Semi Finishing | SNMG120404-DM | 0.40-3.90 | 0.08-0.25 |

|

|

|

| O |

|

| O | O | • | • | O | O |

SNMG120408-DM | 0.80-3.90 | 0.15-0.45 |

|

|

|

| O |

|

| O | O | • | • | O | O |

SNMG120412-DM | 1.20-3.90 | 0.25-0.65 |

|

|

|

| O |

|

| O | O | • | • | O | O |

SNMG120416-DM | 1.80-3.90 | 0.30-0.90 |

|

|

|

| O |

|

| O | O | • | • | O | O |

SNMG150608-DM | 0.80-3.90 | 0.15-0.45 |

|

|

|

| O |

|

| O | O | • | • | O | O |

SNMG150612-DM | 1.20-3.90 | 0.25-0.65 |

|

|

|

| O |

|

| O | O | • | • | O | O |

SNMG150616-DM | 1.80-3.90 | 0.30-0.90 |

|

|

|

| O |

|

| O | O | • | • | O | O |

• : Recommended Grade

O: Optional Grade

Application:

Application for turning and milling carbon and alloy steels, tools steel and stainless steel.

FAQ:

How to choose correct turning insert?

Select insert geometry based on selected operation, for example finishing.

Select the largest possible nose angle on the insert for strength and economy.

Select the insert size depending on the depth of cut

Select the largest possible nose radius for insert strength.

What is the difference between face milling and end milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

Our Company

Package Shipment