Enhanced Performance SNMX Insert for High-speed Cutting Applications Details

Product Information:

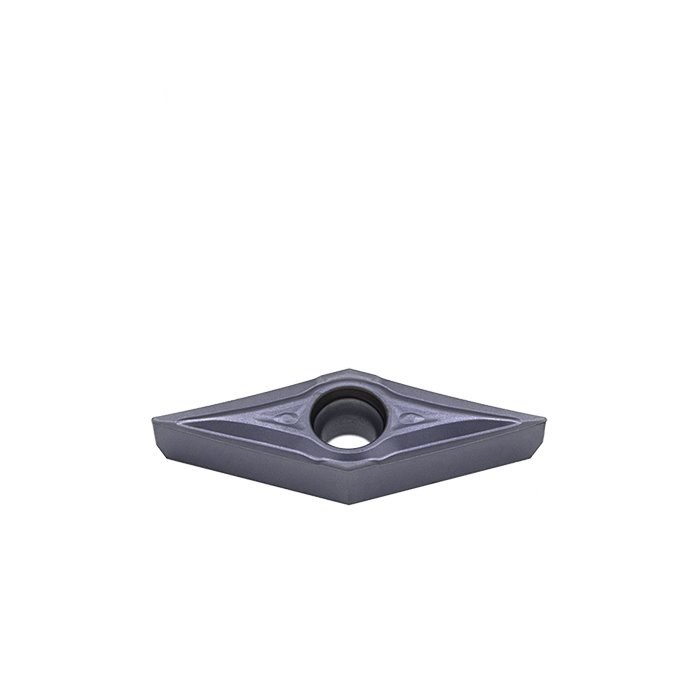

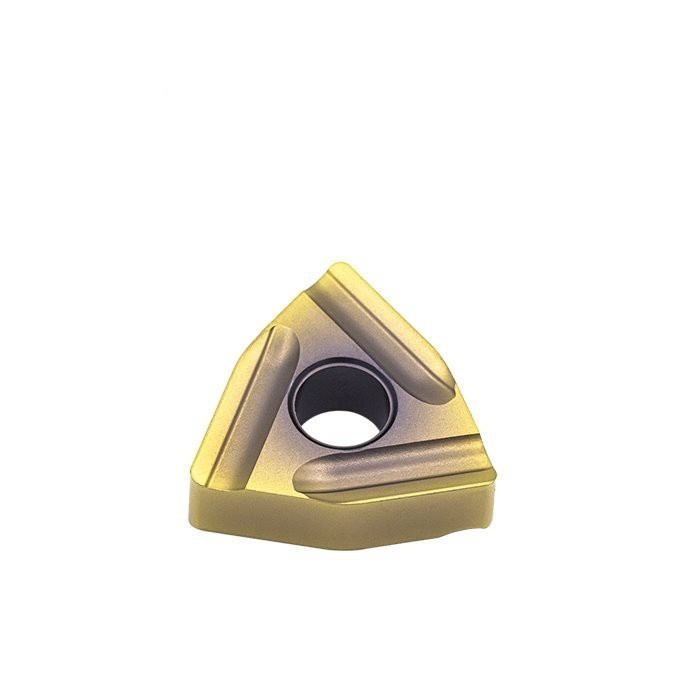

Face mills are tools with a large diameter that are used to cut a wide shallow path for facing operations. with PVD coating is resistant to deformation, good wear resistance and collapse resistance, low co-efficient of friction.

SNMX insert with double-sided negative rake 8-sided shape is highly cost-effective. Double front angle design makes good sharpness and a certain strength.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD |

| PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

SNMX1205ANN-GM | 1.00-6.00 | 0.15-0.50 |

|

| • | • | O | O |

|

|

|

|

|

SNMX1606ANN-GM | 1.00-6.00 | 0.15-0.50 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

Facing is used for machining a large flat area, typically the top of the part in preparation for other milling operations.

SNMX insert with its own wiper edge has a high surface finishing with multiple type of chip breakers. It is suitable for general machining of steel and stainless steel.cast iron.super alloys.

FAQ:

What milling method is generally recommended?

Down milling is generally recommended. With the down milling method, the burnishing effect can be avoided, resulting in less heat & minimal work-hardening tendency.

How is milling done?

The milling process is removing the materials by performing many separate and small cuts. It is accomplished by using a cutter with many teeth, spinning the cutter at a high speed, or advancing the material through the cutter slowly.

Our Company

Package Shipment