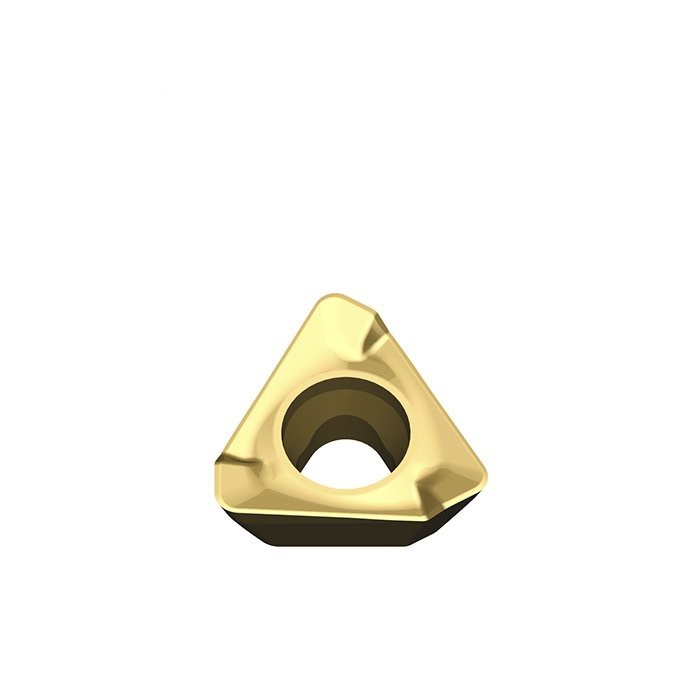

TPKT Insert: Unleash the Cutting Power for Superior Performance Details

Product Information:

90° Shoulder Milling Insert with positive three cutting edges is super high positive helical cutting edge insert. 90° shoulder milling with super smooth and soft machining provides high productivity with maximum number of teeth. Strong tool body with larger core size, Various insert geometry.

TPKT standard carbide (with coating) milling inserts are with strong cutting edges, which provide best reliability and long endurance.

T - triangle shape of milling insert

P - Insert with clearance under main cutting edge (11°).

K- Tolerances and dimensions of carbide

T - Hole through insert and single sided chip breaker.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD |

| PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

TPKT040202R-M | 0.50-3.00 | 0.04-0.08 |

|

| • | • | O | O |

|

|

|

|

|

TPKT040204R-M | 0.50-3.00 | 0.04-0.08 |

|

| • | • | O | O |

|

|

|

|

|

TPKT060302R-M | 1.00-4.00 | 0.04-0.10 |

|

| • | • | O | O |

|

|

|

|

|

TPKT060304R-M | 1.00-4.00 | 0.04-0.10 |

|

| • | • | O | O |

|

|

|

|

|

TPKT060308R-M | 1.00-4.00 | 0.04-0.10 |

|

| • | • | O | O |

|

|

|

|

|

TPKT100404R-M | 2.00-6.00 | 0.05-0.12 |

|

| • | • | O | O |

|

|

|

|

|

TPKT100408R-M | 2.00-6.00 | 0.05-0.12 |

|

| • | • | O | O |

|

|

|

|

|

TPKT100416R-M | 2.00-6.00 | 0.05-0.12 |

|

| • | • | O | O |

|

|

|

|

|

TPKT150508R-M | 3.00-9.00 | 0.07-0.17 |

|

| • | • | O | O |

|

|

|

|

|

TPKT150516R-M | 3.00-9.00 | 0.07-0.17 |

|

| • | • | O | O |

|

|

|

|

|

TPKT150524R-M | 3.00-12.00 | 0.07-0.17 |

|

| • | • | O | O |

|

|

|

|

|

TPKT190608R-M | 4.50-12.00 | 0.09-0.22 |

|

| • | • | O | O |

|

|

|

|

|

TPKT190616R-M | 4.50-12.00 | 0.09-0.22 |

|

| • | • | O | O |

|

|

|

|

|

TPKT190624R-M | 4.50-12.00 | 0.09-0.22 |

|

| • | • | O | O |

|

|

|

|

|

TPKT190632R-M | 4.50-12.00 | 0.09-0.22 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

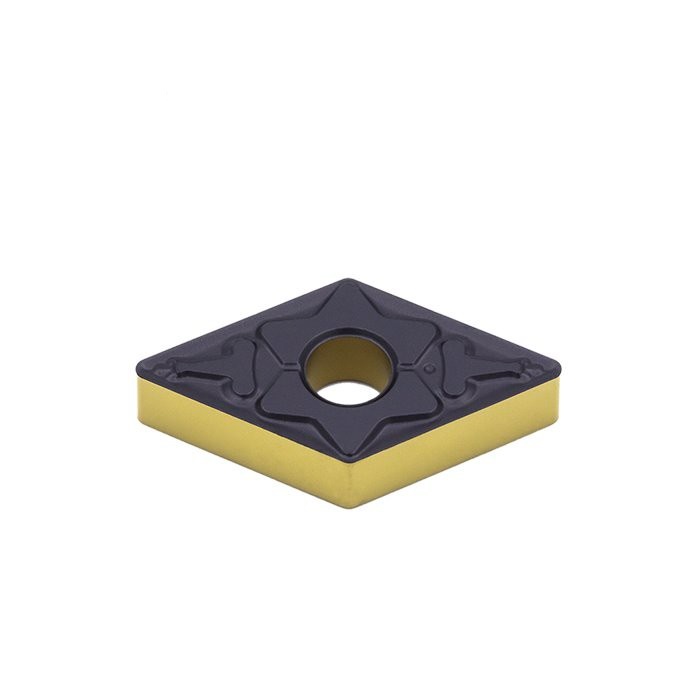

Applications:

For general machining, stainless steel and light machining with sharp cutting edge, steel and non-ferrous materials, chip splitter insert.It widely used in medium-light application & in stainsless steel machining.

FAQ:

What is shoulder milling?

Shoulder milling generates two faces simultaneously, which requires peripheral milling in combination with face milling. Shoulder milling can be performed by traditional square shoulder cutters, and also by using end milling cutters, long-edge cutters and side and face milling cutters.

What milling method is generally recommended?

Down milling is generally recommended. With the down milling method, the burnishing effect can be avoided, resulting in less heat & minimal work-hardening tendency.

Our Company

Package Shipment