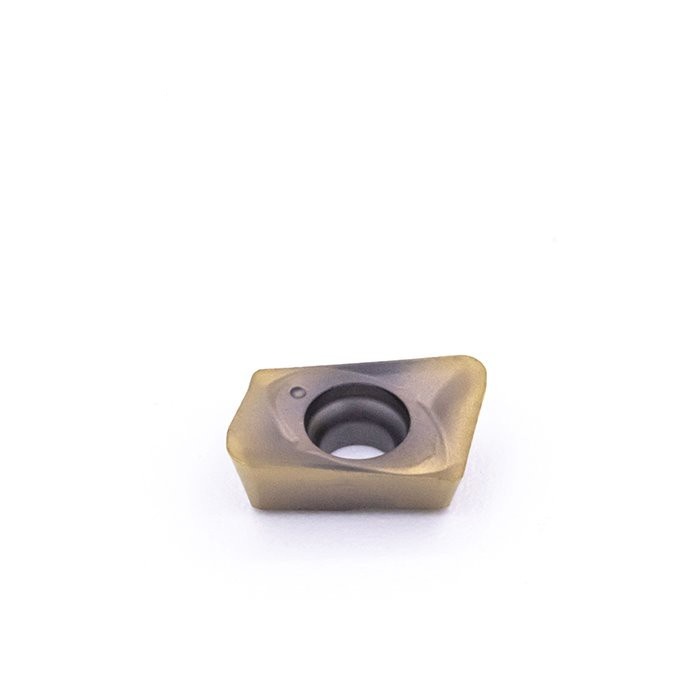

RPHX High-temp Alloy Insert for Reliable Machining in Extreme Conditions Details

Product Information:

RPHX round milling inserts with specially shaped indexing grooves. Single-sided positive round inserts have a specially shaped bottom and side surfaces used for indexing and to prevent the insert from rotating.

Application:

Round milling inserts with specially shaped indexing grooves. Used for roughing and finishing applications on alloyed and stainless steels, specifically in the die and mold industry

FAQ:

How to choose correct turning insert?

Select insert geometry based on selected operation, for example finishing.

Select the largest possible nose angle on the insert for strength and economy.

Select the insert size depending on the depth of cut

Select the largest possible nose radius for insert strength.

What is the difference between face milling and end milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

Our Company

Package Shipment