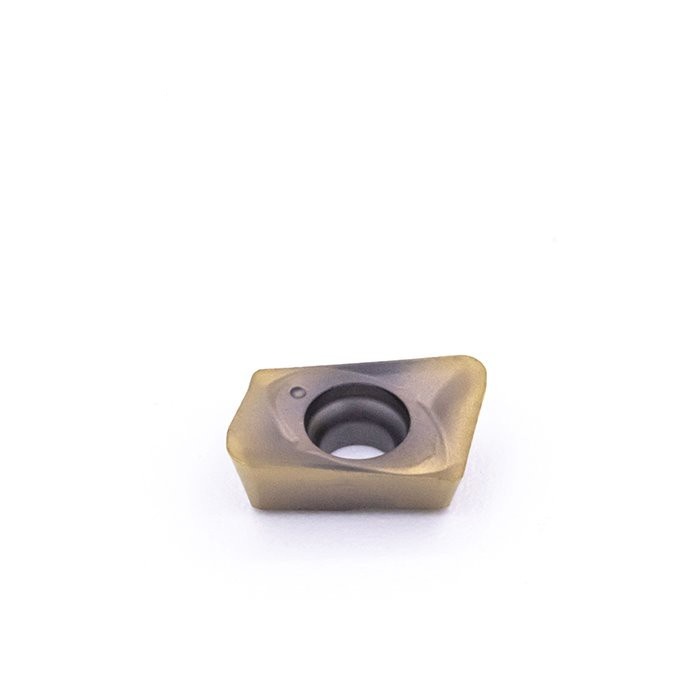

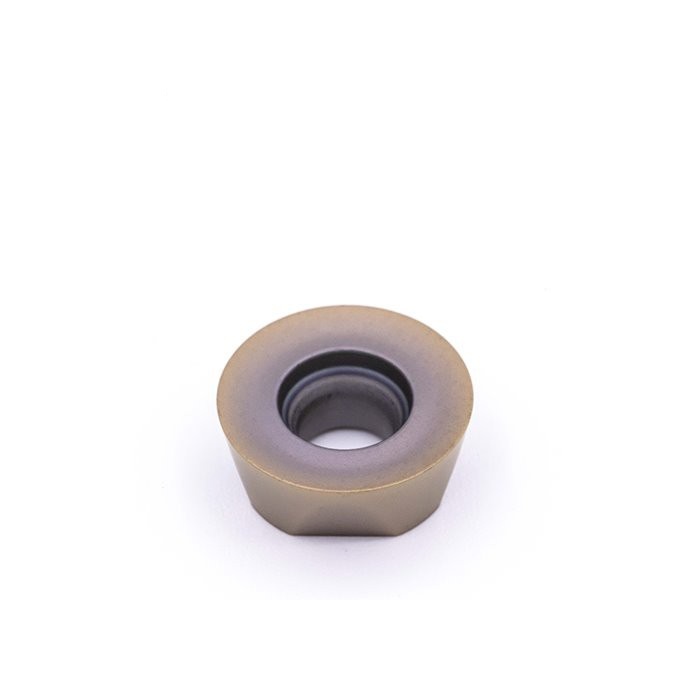

BLMP Insert for Precise and Stable Machining in Fine Finishing Details

Product Information:

BLMP high feed carbide insert with double sided 4 edged insert.

Strong substrate, fine micro grain wc, has high wear resistance. PVD Coating: Balzers coating furnace, nano with high Al. multi coating, suitable for general machining. Precision: ground insert. CNC periphery grinding machine. Cutter with inner coolant hole. big rake angle made easy cutting, 4 cutting edges to save cost.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

BLMP0402R-GM | 0.10-0.50 | 0.20-1.50 |

|

| • | • | O | O |

|

|

|

|

|

BLMP0603R-GM | 0.10-1.00 | 0.30-2.50 |

|

| • | • | O | O |

|

|

|

|

|

BLMP0904R-GM | 0.10-1.50 | 0.30-3.50 |

|

| • | • | O | O |

|

|

|

|

|

BLMP1105R-GM | 0.30-2.00 | 0.30-4.00 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

BLMP carbide inserts for high feed milling . Used for processing steel, stable quality.

FAQ:

How do I choose the milling insert?

Selecting the milling insert based on the application of demands and the space for the cutting tools. the larger of the insert.the better of the stability . For heavy machining, the insert size is normally above 1 inch. finishing, the size cans be reduced.

What is high speed machining?

High-feed milling is a machining method that pairs shallow depth of cut with high feed rate. It can achieve a very high metal-removal rate, high-speed machining to reduce cycle time, increase tool life and productivity.

Our Company

Package Shipment