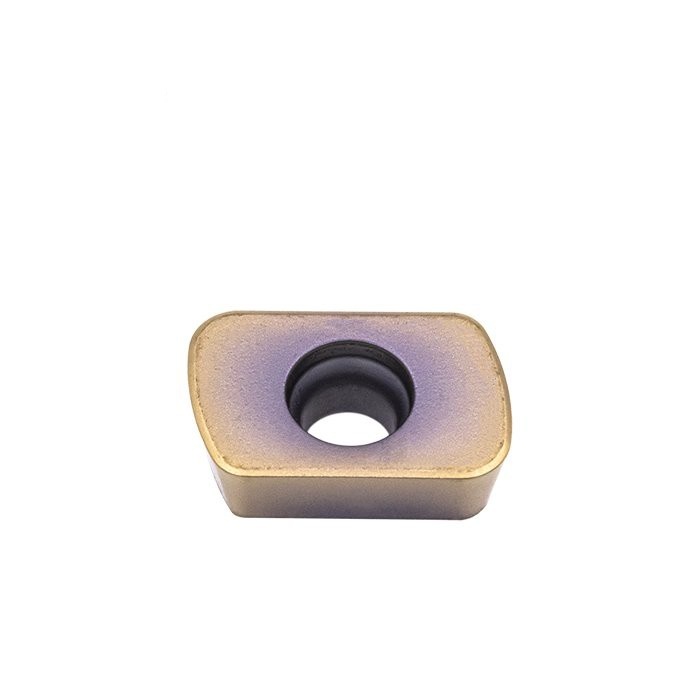

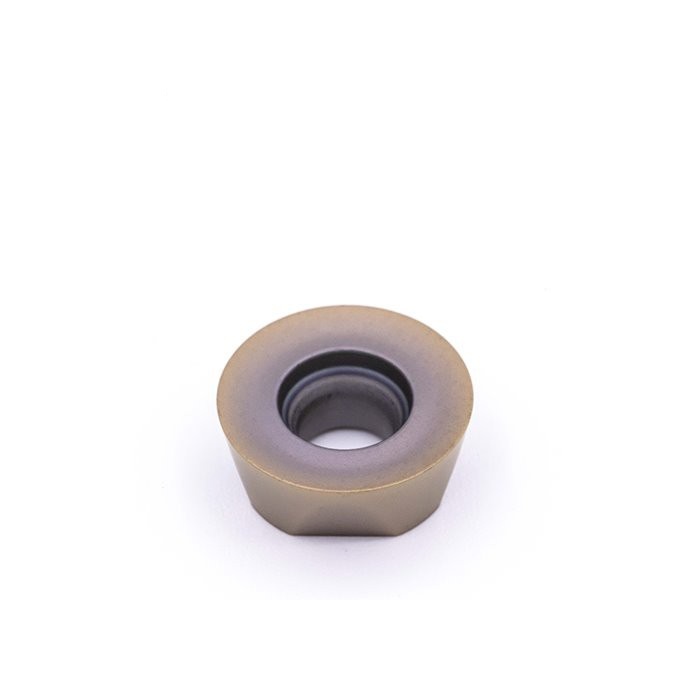

WNMU Insert for Efficient Chip Removal in Milling Operations Details

Product Information:

Shoulder milling cutters are indexable designed with wedge type clamping or screw-on type clamping to achieve high-quality machining.

WNMU is one kind of double-sided square shoulder milling insert with sharp cutting edge and small cutting resistance. Thick specification design for stronger collapse resistance. No directional blade, left and right knife can be used; 6 double-sided blades is very economical.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

WNMU050408EN-GM | 0.50-5.00 | 0.10-0.30 |

|

| • | • | O | O |

|

|

|

|

|

WNMU080608EN-GM | 0.80-8.00 | 0.10-0.30 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application

Inserts have strongly supported cutting edge. Recommended for different purposes and applications for machining steel, stainless steel.

FAQ:

What is an indexable drill bit?

Indexable drill bits have a fluted body that accepts replaceable cutting inserts to form a cutting edge for drilling holes into workpieces. The inserts can be rotated (indexed) to expose a fresh cutting edge when the old one dulls.

What is shoulder milling?

Shoulder milling generates two faces simultaneously, which requires peripheral milling in combination with face milling. Shoulder milling can be performed by traditional square shoulder cutters, and also by using end milling cutters, long-edge cutters and side and face milling cutters.

Our Company

Package Shipment