Tungaloy cnc grooving inserts WGE30 GH730 Details

Advantage of Tungaloy cnc grooving inserts :

1. 100% original Japan Tungaloy brand.

2. Grade: Various grades for choice

3. Advanced production equipments and testing equipments.

4. Best price and fast delivery.

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precision grinding

7. Small orders are acceptable

Specifications of Tungaloy cnc grooving inserts :

Item name: Tungaloy cnc grooving inserts

Brand: Tungaloy

Model: WGE30 GH730

Grade: GH730

Coating: CVD/PVD

Workpiece: steel/stainless steel/cast iron

Color: Golden/grey/black

Application :Grooving inserts

Meterial :Tungsten carbide

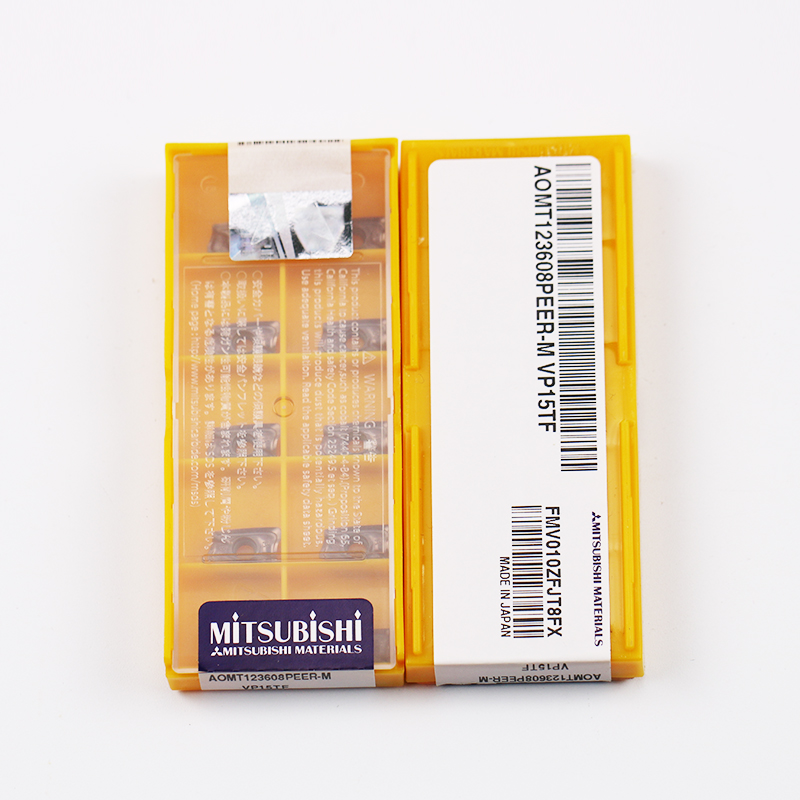

Package: 10 pcs in a plastic box

Shipping method of Tungaloy cnc grooving inserts :

Package: 10 pcs in a plastic box,then by a carton

International express: DHL,TNT,UPS,EMS etc

Our advantage:

1.We have in stock a wide range of lathe tools s, with various chip breaking and coating grades to suit different types of application conditions.

2.lathe tools s for, turning, milling, boring, drilling, threading turning and parting, cermet insertss, pcd and cbn insertss.

3.Our team of experienced engineers can help design and manufacture custom specification lathe tools s for your specific application.

4.We guarantee rapid response to quotes and excellent delivery times.

5. We are successfully meeting the varied requirements of our clients by providing the best quality range of lathe tools .

6. Our products are excellent and cheap.

Our Agent Brand Include:

ZCCCT, Kennametal, Tungaloy, Korloy, Sumitomo, Valenite, Walter, Taegutec, Kyocera, Iscar, Carmex, SECO, Dijet, Hitachi, OSG, Lamina, etc

Our Company

Package Shipment