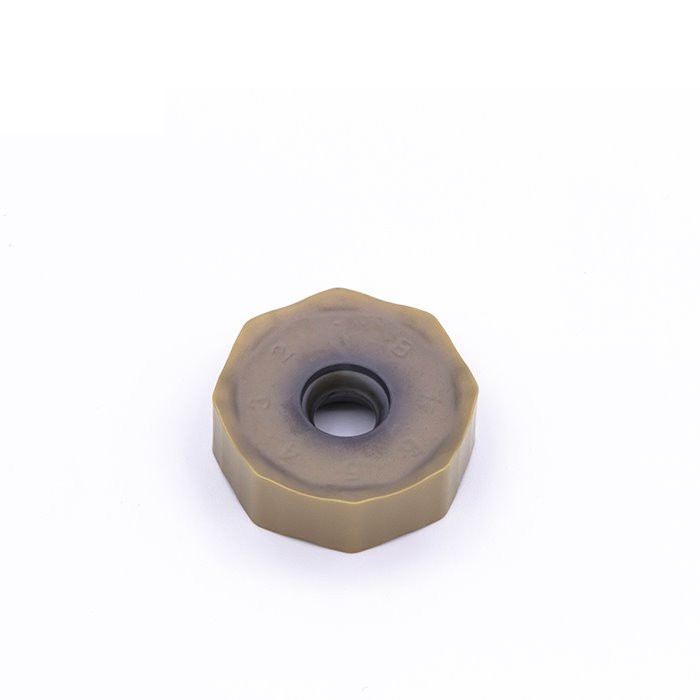

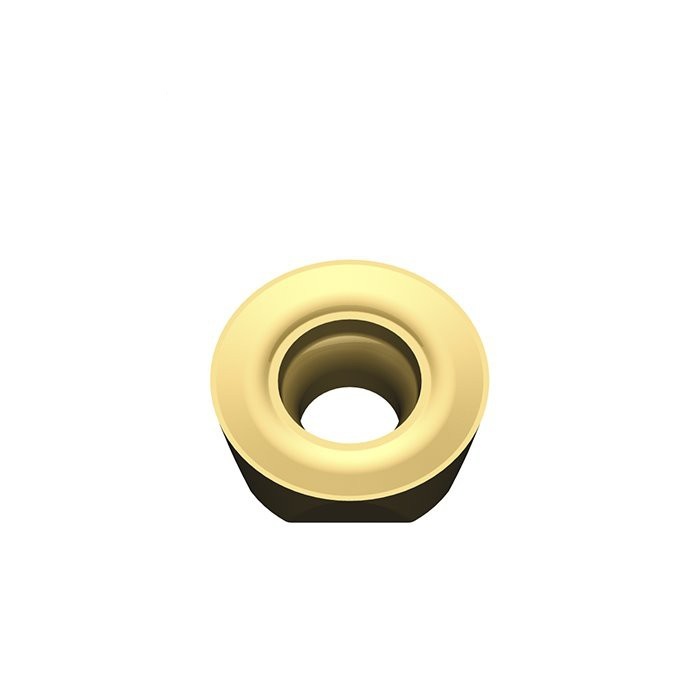

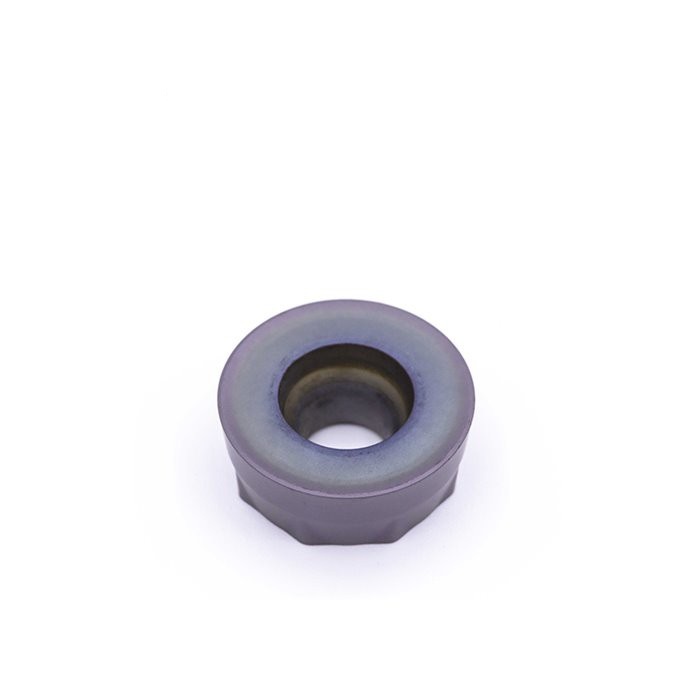

SNGX Insert for Exceptional Chip Control and Improved Machining Efficiency Details

Product Information:

Double-sided square high feed milling insert SNGX with 0 degree clearance angle. Negative rake. an indexing accuracy according to ISO-tolerance class-G and M geometry with rounded cutting edges and facet.A strong main cutting edge ensures high levels of durability and process security – especially when machining corners inside a pocket. With eight cutting edges, the square-shaped SNGX also represents an extremely economical solution.

Specifications:

Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525I | VY1028 | VY1330 |

SNGX090408-GF | 2.50-7.50 | 0.08-0.15 |

|

| • | • | O | O |

|

|

|

|

|

SNGX090411-GF | 2.50-7.50 | 0.08-0.15 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

Primary Material Application: High-Temperature Alloys, Stainless Steel, Steel.

FAQ:

What are face mills?

Face milling is a machining process in which the milling cutting is placed perpendicular to the workpiece. The milling cutting is essentially positioned “face down” towards the top of the workpiece. When engaged, the top of the milling cutting grinds away at the top of the workpiece to remove some of its material.

What is the difference between face milling and end milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

Our Company

Package Shipment