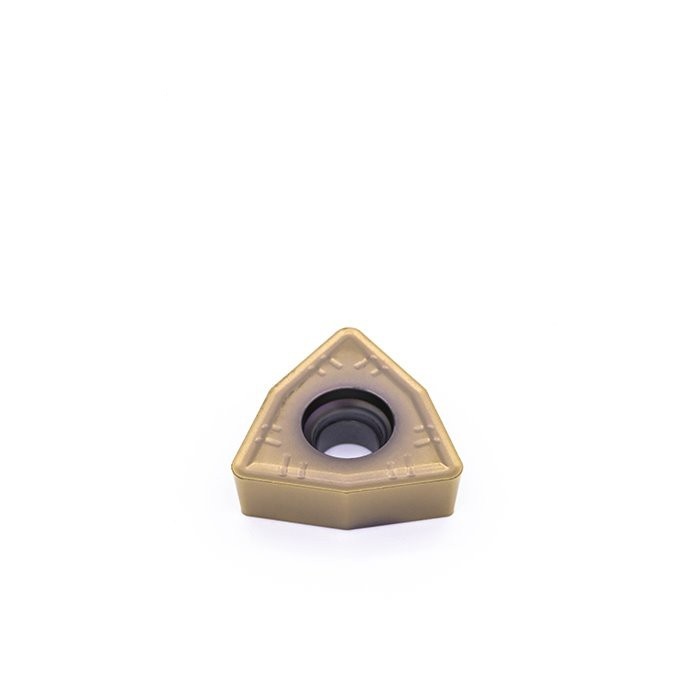

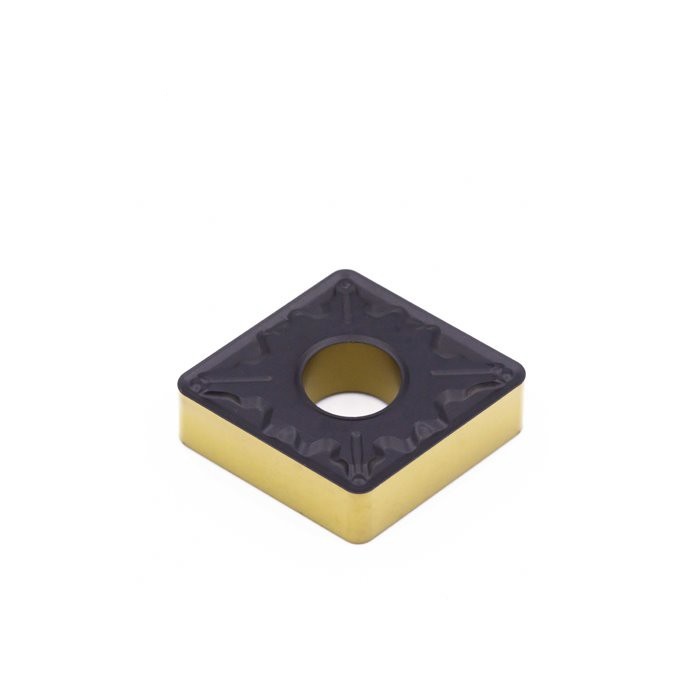

RDKT Insert: Maximize Productivity with Long-lasting Performance Details

Product Information:

RDKT round shape milling inserts.Solid carbide provides better rigidity than high speed steel.

The R-type inserts have extra-strong cutting edge to meet the requirements for machining of curved surface of die.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1025 | VT1325 | VT1525 | VT1328 | VY1010 | VY1520 | VY1525 | VY1028 | VY1330 |

RDKT0803MO | 1.00-3.00 | 0.05-0.25 |

|

| • | • | O | O |

|

|

|

|

|

RDKT10T3MO | 1.50-4.00 | 0.05-0.30 |

|

| • | • | O | O |

|

|

|

|

|

RDKT1204MO | 1.50-5.00 | 0.05-0.35 |

|

| • | • | O | O |

|

|

|

|

|

RDKT1604MO | 2.00-6.50 | 0.10-0.40 |

|

| • | • | O | O |

|

|

|

|

|

RDKT1605MO | 2.00-6.50 | 0.10-0.40 |

|

| • | • | O | O |

|

|

|

|

|

RDKT1606MO | 2.00-6.50 | 0.10-0.40 |

|

| • | • | O | O |

|

|

|

|

|

RDKT2006MO | 3.00-8.00 | 0.10-0.40 |

|

| • | • | O | O |

|

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

It suitable for most materials.Mainly focuses on face milling and cavity profile milling of steel alloy steel, stainless steel and cast iron.

FAQ:

What milling method is generally recommended?

Down milling is generally recommended. With the down milling method, the burnishing effect can be avoided, resulting in less heat & minimal work-hardening tendency.

How is milling done?

The milling process is removing the materials by performing many separate and small cuts. It is accomplished by using a cutter with many teeth, spinning the cutter at a high speed, or advancing the material through the cutter slowly.

Our Company

Package Shipment