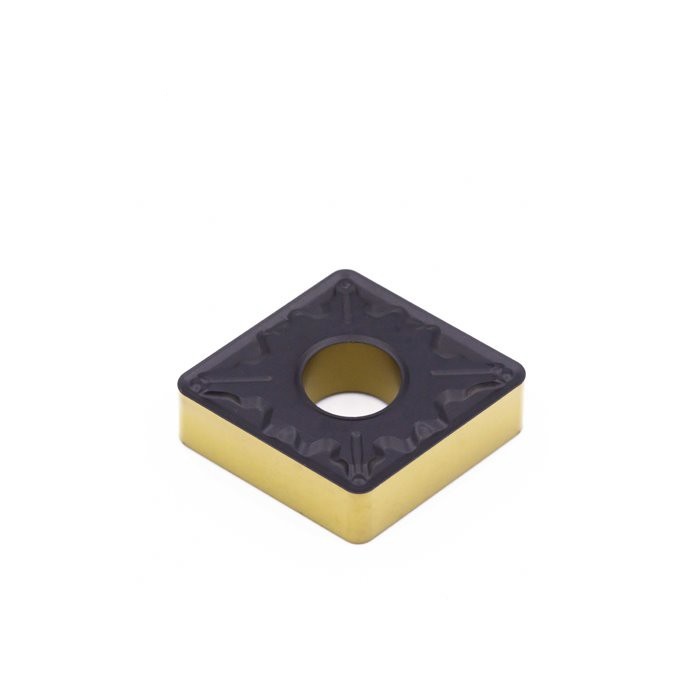

CNC Carbide Tool Insert for Precise and Stable Machining Results Details

Product Information:

Parting and grooving inserts are inserts for cylinder parting and grooving, including to the outer circular, the inner hole groove, the cutter withdrawal groove, and the end face groove.ERMN insert suitable for parting, grooving, and turning. Easy machining and unobstructed chip flow lead to improved surface quality.Geometry of ERMN cutting insert is shaped for profile turning. Without hole through the insert. Strong cutting edges offer best reliability in hard cutting conditions and long endurance.

Specifications:

| Type | Fn (mm/rev) | Grade |

CVD | PVD |

VT4215 | VT4225 | VT4235 | VT4315 | VT4325 | VT1025 | VT1325 | VT1328 | VT1528 | VY1010 | VY1525 |

ERMN200-M | 0.05-0.15 |

|

|

|

| • | O | • |

| O |

| O |

ERMN300-M | 0.08-0.18 |

|

|

|

| • | O | • |

| O |

| O |

ERMN400-M | 0.10-0.20 |

|

|

|

| • | O | • |

| O |

| O |

ERMN500-M | 0.12-0.23 |

|

|

|

| • | O | • |

| O |

| O |

ERMN600-M | 0.15-0.27 |

|

|

|

| • | O | • |

| O |

| O |

ERMN800-M | 0.18-0.35 |

|

|

|

| • | O | • |

| O |

| O |

• : Recommended Grade

O: Optional Grade

Application:

Recommended for different purposes and applications in parting and grooving .It performs well on turning material steel, stainless steel and cast iron.

FAQ:

What is grooving turning?

Grooving is one type of specific turning operation that cut grooves or forms a narrow cavity of a certain depth on external, internal surfaces, cylinder, cone, or a face of the part.

What are the important factors in parting and grooving?

In parting and grooving, the process security and productivity are two important factors. With the correct setup and choice of tools, many difficulties that can be avoided when parting-off.

Our Company

Package Shipment