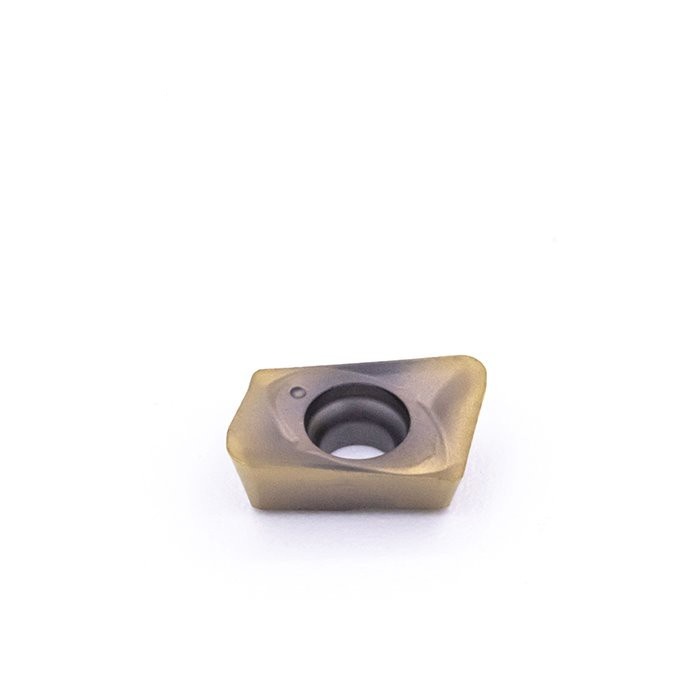

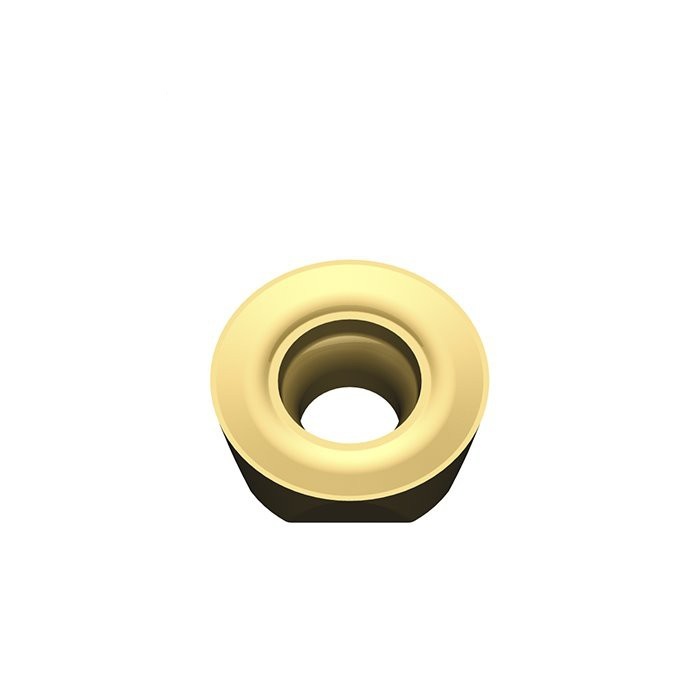

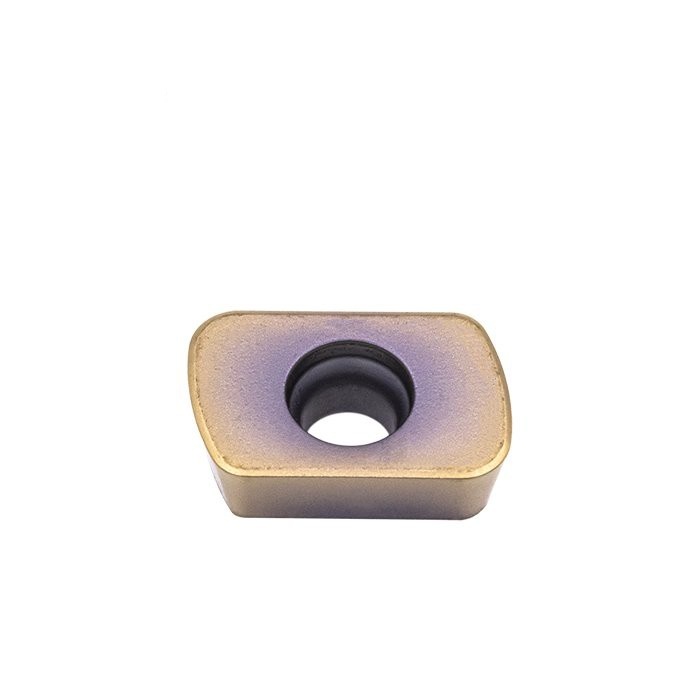

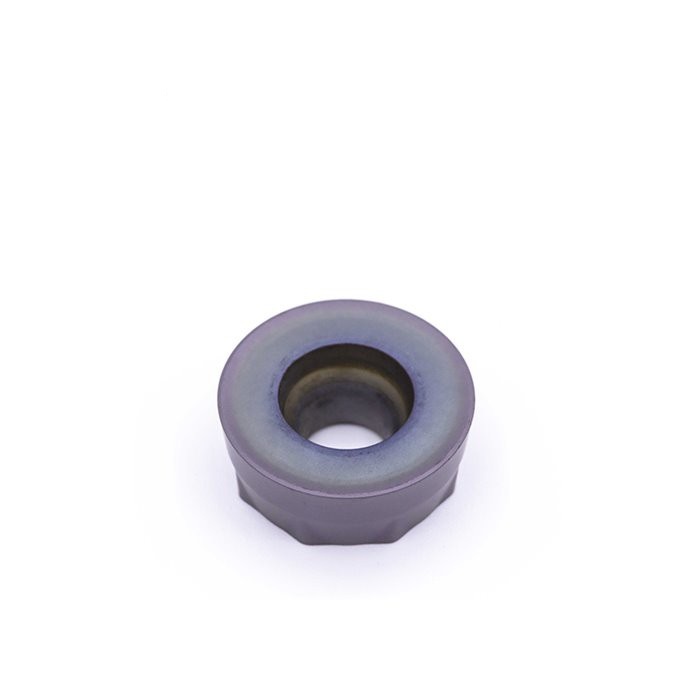

BDMT Insert for High-speed Turning and Boring Operations Details

Product Information:

Superior wear and oxidation-resistant on micro-grain carbide substrate. Insert or replaceable rhomboidal cutting item with two cutting corners at eighty five degrees, four sides and four internal angles none of which are equal to ninety degrees.

Specifications:

| Type | Ap (mm) | Fn (mm/rev) | CVD | PVD |

VT3020 | VT3040 | VT1015 | VT1025 | VT1824 | VT1825 | VT1525 | VT1828 | VY1010 | VY1520 | VY1525 | VY1029 |

BDMT11T302ER-JT | 2.0-6.0 | 0.06-0.15 |

|

| O | • | O | • | • | O |

|

|

|

|

BDMT11T304ER-JT | 2.2-8.0 | 0.08-0.15 |

|

| O | • | O | • | • | O |

|

|

|

|

BDMT11T308ER-JT | 2.5-10.0 | 0.10-0.18 |

|

| O | • | O | • | • | O |

|

|

|

|

BDMT11T312ER-JT | 2.8-10.0 | 0.08-0.2 |

|

| O | • | O | • | • | O |

|

|

|

|

• : Recommended Grade

O: Optional Grade

Application:

For shoulder milling of steel and stainless steel.

FAQ:

What is called milling?

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head speed, and pressure.

What are types of milling?

Shoulder milling.

Face milling.

Profile milling.

Groove milling and parting off.

Chamfer milling.

Turn milling.

Gear machining.

Holes and cavities/ pocketing.

Our Company

Package Shipment