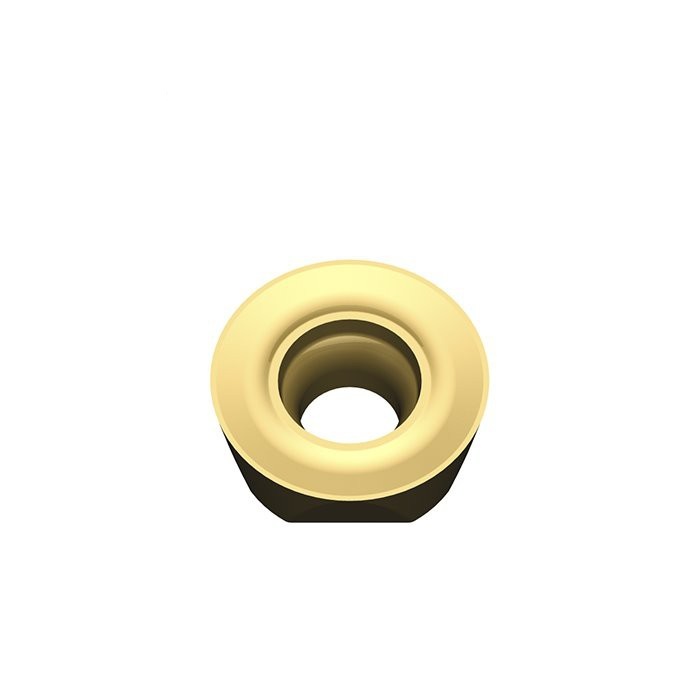

RPKT Insert for High-feed Milling and Roughing Applications Details

Product Information:

Milling Insert RPKT with positive rake shape round. Advanced coating provides improved toughness and strength.Used-edge detection reduces waste and cost per edge. Greater process predictability in steels and cast irons.

Application:

Application for cast iron, non-ferrous materials, plastics and other tough-to-machine materials.

FAQ:

What are face mills?

Face milling is a machining process in which the milling cutting is placed perpendicular to the workpiece. The milling cutting is essentially positioned “face down” towards the top of the workpiece. When engaged, the top of the milling cutting grinds away at the top of the workpiece to remove some of its material.

What is the difference between face milling and end milling?

These are two of the most prevalent milling operations, each using different types of cutters – the and mill and the face mill. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

Our Company

Package Shipment