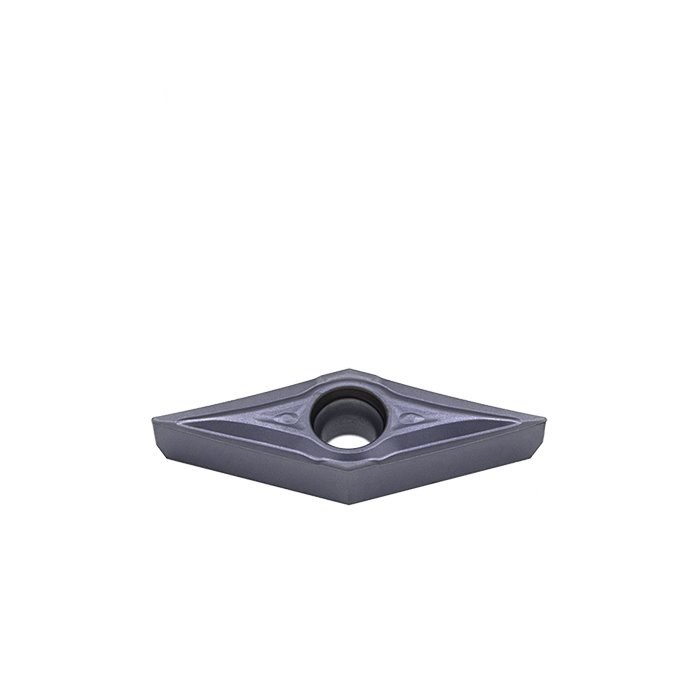

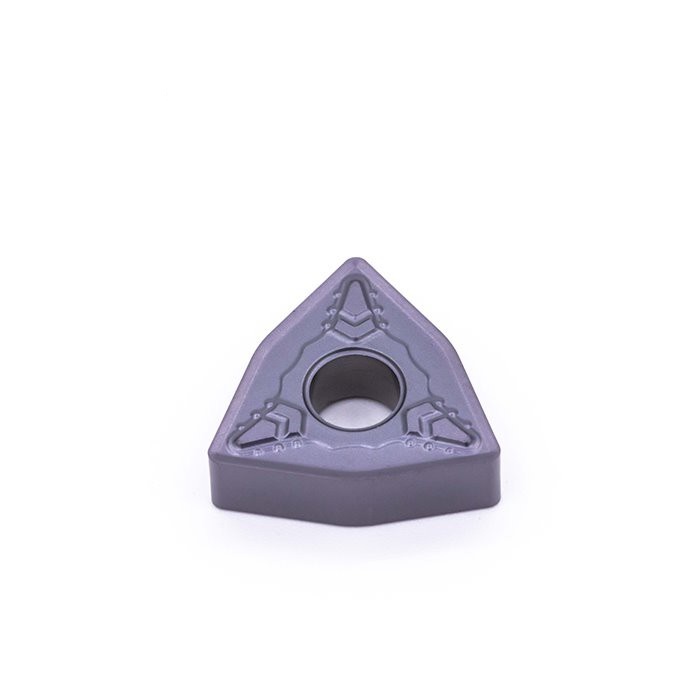

Efficient EDC Grooving Insert for Precision Machining Operations Details

Product Information:

EDC-300R0.4 double-ended inserts for parting and grooving with high clamping rigidity. For stable tool life and accuracy.It is a cost-efficient solution for depths in which 2-edged inserts can be used for parting off and external grooving.

Application:

The inserts are mainly used for parting, external grooving, face grooving, internal grooving, profiling and hard part turning.Roughing to finishing.

FAQ:

What is grooving used for?

Grooving or recessing operations, sometimes also called necking operations, are often done on work piece shoulders to ensure the correct fit for mating parts. When a thread is required to run the full length of the part to a shoulder, a groove is usually machined to allow full travel of the nut.

What is face grooving?

When making an axial groove on the face of a component it is important to choose the correct tools. The bending radius of the groove will determine the curve of the tool. Chip evacuation can be a problem in face grooving due to the curved groove.

Our Company

Package Shipment