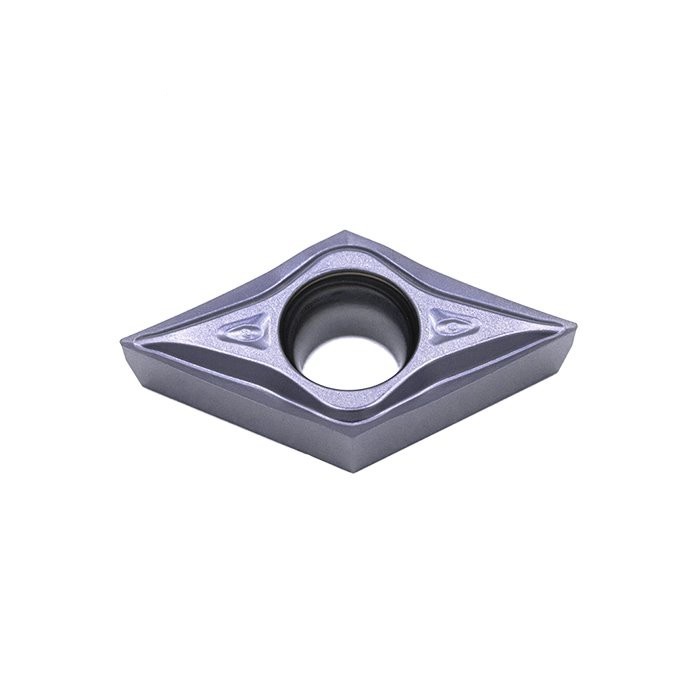

16IR Insert for Precision Threading Operations Details

Product Information:

16IR Internal thread insert, material: carbide.the insert is 60 degree angle standard metric. Insert purpose is for internal turning. Orientation of insert is right. Internal threading applications in three different geometries: all-round, sharp and a chip breaking C-Geometry.Good wear resistance and edge sharpness..High abrasion performance and pertinence.

Specifications:

| Type | Range of thread pitch | Insert Dimensions (mm) | Grade |

mm | Pitch/Inch | IC | S | X | Y | VT1320 | VT1520 |

16ERA60 | 0.5-1.5 | 48-16 | 9.525 | 3.52 | 0.9 | 0.8 | • | O |

16ERAG60 | 0.5-3.0 | 48-8 | 9.525 | 3.52 | 1.7 | 1.2 | • | O |

16ERG60 | 1.75-3.0 | 14-8 | 9.525 | 3.52 | 1.7 | 1.2 | • | O |

22ERN60 | 3.5-5.0 | 7-5 | 12.7 | 4.65 | 2.5 | 1.7 | • | O |

11IRA60 | 0.5-1.5 | 48-16 | 6.35 | 3.52 | 0.9 | 0.8 | • | O |

16IRA60 | 0.5-1.5 | 48-16 | 9.525 | 3.52 | 0.9 | 0.8 | • | O |

16IRAG60 | 0.5-3.0 | 48-8 | 9.525 | 3.52 | 1.7 | 1.2 | • | O |

16IRG60 | 1.75-3.0 | 14-8 | 9.525 | 3.52 | 1.7 | 1.2 | • | O |

22IRN60 | 3.5-5.0 | 7-5 | 12.7 | 4.65 | 2.5 | 1.7 | • | O |

• : Recommended Grade

O: Optional Grade

Application

Application for various steel threading operations.The type of carbide grade and the coating on inserts is originally intended for turning steel and stainless steel, but it also performs when turning other alloys.

FAQ:

What is a thread insert called?

A threaded insert that is inserted into an object to add a threaded hole.

How do threaded inserts work in metal?

When the thread inserts for metal.the inserts will create a metal threading point which can be installed and removed many times.

Our Company

Package Shipment