Choosing the Right Turning Inserts for Your Machining Needs

Home › Product News › Choosing the Right Turning Inserts for Your Machining Needs

Home › Product News › Choosing the Right Turning Inserts for Your Machining Needs

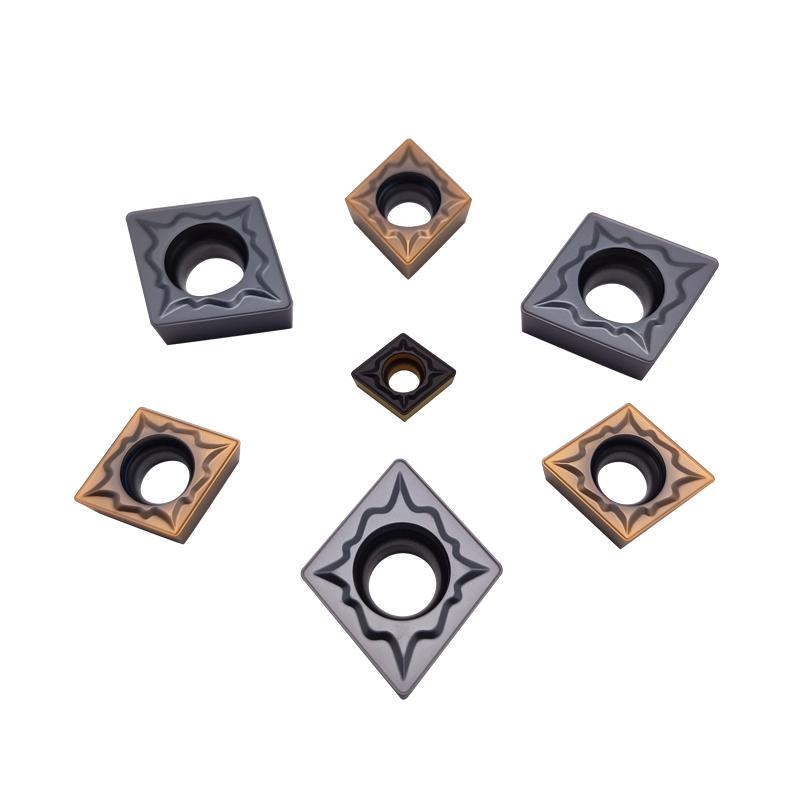

If you are in the machining industry, you know that selecting the right turning insert is an important decision. It is essential to choose the correct insert for your machining needs to ensure that the job is done correctly and efficiently. Here are a few tips to help you make the right decision when choosing the right turning inserts for your machining needs.

First, it is important to consider the type of material you are machining. Different materials require different turning inserts. For example, aluminum requires different inserts than steel. Knowing the type of material you are working with will help you narrow down your selection when choosing the right turning inserts.

Second, consider the geometry of the insert. Different geometries provide different levels of cutting performance. For example, a negative rake angle will reduce cutting forces and provide a smoother cut, while a positive rake angle will provide a better finish. Making sure to select an insert with the correct geometry can help you achieve the desired results.

Third, think about the cutting environment. Different cutting environments require different turning inserts. For example, wet machining requires different inserts than dry machining. You should also consider the speed and feed rate when selecting the correct inserts.

Finally, consider the cost. Different inserts have different prices. It is important to consider the cost of the inserts when making your decision. You should also consider the cost of replacing inserts if they become damaged or worn out.

Choosing the right turning inserts for your machining needs is essential for ensuring the job is done correctly and efficiently. Make sure to consider the type of material, geometry, cutting environment, and cost when selecting the right inserts for your machining needs.

Write a Comment